Precision electronics inspection is demanding, which FA lens is best suited?

In the current rapid development of science and technology, the precision electronics industry continues to move towards the development of high precision and miniaturization. From smart phone chips to wearable devices to tiny parts, precision electronic products in the production process, the accuracy, stability and reliability of the inspection link puts forward almost stringent requirements. As a key component in the machine vision inspection system, the performance of the FA lens is directly related to the accuracy of the inspection results, and the selection of suitable FA lenses has become the core point of precision electronic inspection.

Fixed-focus macro lenses: a great tool for cosmetic defect and character detection

Among the many types of FA lenses, fixed-focus macro lenses excel in the detection of scratches and defects in precision electronics and character detection. POMEAS fixed-focus macro lenses utilize advanced optical design and precision manufacturing processes to provide extremely high resolution and excellent macro shooting capabilities. When inspecting the appearance of precision electronic components, it is able to clearly image tiny scratches and defects, even micron-level defects are invisible. In the character detection scene, whether it is a very small font logo or a fine line number, fixed-focus macro lens can be accurately captured for the subsequent image analysis and judgment to provide a clear and accurate image base, to ensure that the quality of the product appearance in line with high standards.

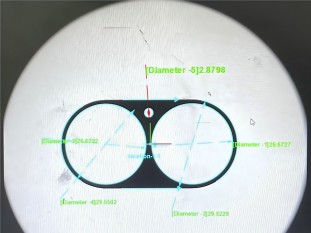

Telecentric Lenses: The Best Choice for Precision Dimensional Inspection

Telecentric lenses are the perfect choice for dimensional inspection of precision electronics. POMEAS telecentric lenses have unique optical characteristics that effectively eliminate dimensional measurement errors due to variations in object distance, ensuring highly accurate dimensional measurements over the entire field of view. In the dimensional inspection of precision electronic components, the dimensional accuracy of the components is often required to be controlled within a very small tolerance range. The telecentric lens, through its nearly parallel light design, makes the measurement results independent of the position and angle of the object, and is able to accurately measure the length, width, height, and other dimensional parameters of the components, which provides a reliable dimensional inspection guarantee for the production of precision electronics.

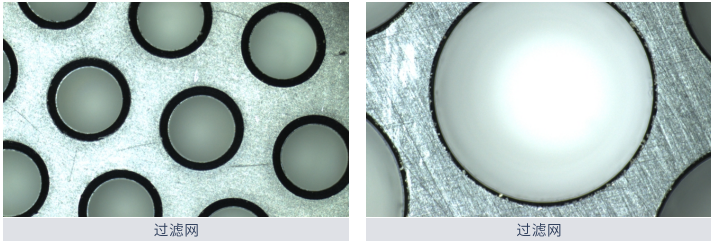

Zoom lenses: flexible assistants for microscopic observations

Variable zoom lenses bring greater flexibility to precision electronics inspection. POMEAS zoom lenses can continuously change the focal length within a certain range to realize different magnification of the product. When it is necessary to observe the microstructure of the electronics, the operator can easily magnify the product to the required magnification through the zoom lens, and clearly observe the internal microstructure of the electronic components, such as the circuit layout inside the chip, the microstructure of the solder joints, etc. This flexible zoom function allows the inspector to observe the microstructure of the electronic components. This flexible zoom function allows inspectors to have a comprehensive and in-depth understanding of the microscopic state of the product, which meets the diversified needs for microscopic observation in precision electronics inspection.

In the face of the high demands of precision electronics inspection, POMEAS provides the industry with a comprehensive and precisely adapted inspection solution with a wide range of FA lenses with excellent performance.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com