How to switch the machine vision light source for different needs of multi-station inspection?

In modern industrial automated production, machine vision inspection technology plays a key role, and vision light source as an important part of the machine vision system, its performance advantages and disadvantages directly affect the accuracy and stability of the detection results.

In all types of inspection solutions, vision light sources provide clear and accurate image information for the inspection system. The right light source can enhance the contrast between the target object and the background, highlight the inspection features, reduce image noise interference, so that the inspection equipment to accurately identify the product defects, dimensional deviations and other issues. Whether it is the precision inspection of tiny electronic components or the surface quality inspection of large mechanical parts, the visual light source is the core element to ensure the accuracy and efficiency of the inspection.

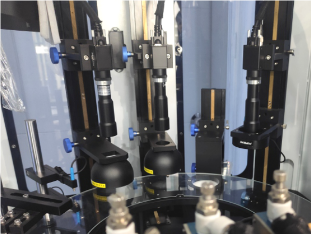

Take common vision inspection equipment as an example, in each inspection lens with a vision light source, seemingly simple configuration, but contains the key to meet the complex inspection requirements.

In the electronics manufacturing industry, a multi-station inspection equipment, the first station may need to detect the chip's pin flatness, which requires the light source can provide high brightness, uniform diffuse reflection of light, in order to clearly present the pin's subtle shape and surface conditions;

When detecting circuit patterns on the chip surface, it may be necessary to use low-angle coaxial light to highlight the edge features of the circuit lines and enhance the contrast of the image.

Q: How does POMEAS' machine vision light source enable flexible switching to meet these diverse needs?

Intelligent control system: By pre-setting the light source parameters for different stations, such as brightness, color, irradiation angle, etc., the control system is able to quickly and accurately adjust the light source output according to the switching of the inspection process, ensuring that each station can obtain the most suitable light conditions.

Light source modules: these modules are compact in design and easy to install, in the face of different inspection needs, the operator can replace the light source module in a short time to achieve rapid switching of different types of light sources, greatly improving the flexibility and adaptability of the inspection equipment.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION