Testing Background

In the mold manufacturing industry, accurate measurement and analysis of mold contour is of vital importance to ensure the quality of molds, improve product accuracy and optimize the production process. Traditional mold contour measurement methods often suffer from low efficiency, limited accuracy and poor adaptability to complex shapes. With the continuous development of optical measurement technology, we propose a set of mold contour scanning solutions based on advanced optical equipment and software systems, aiming to provide mold manufacturers with efficient, accurate and comprehensive measurement solutions.

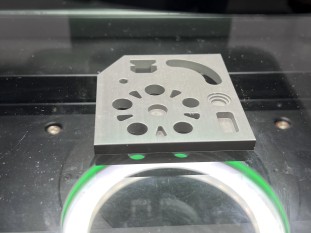

Mold Profile Scanning Solution

1. Optical lens module

POMEAS 6.5X motorized zoom lens was selected as the core optical lens module. The lens has a motorized zoom function, which can flexibly adjust the magnification within a certain range, facilitating clear imaging of different parts of the mold and different detailed features. Its high optical resolution ensures that the minute details of the mold contour can be captured, providing a reliable image base for subsequent accurate measurement and analysis. Both the fine grain and complex edge shapes of the mold can be accurately rendered.

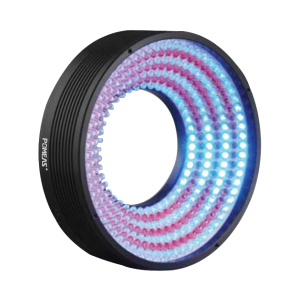

2. Light source system

Adopt five rings and eight zones ring light source to build the optical system. This specially designed ring light source can provide multi-directional and multi-angle illumination effects, effectively reduce shadows and reflections, and significantly improve the contrast and clarity of the mold contour image. By independently controlling the brightness of the light source in different rings and zones, the illumination can be flexibly adjusted according to the material and shape of the mold as well as the measurement requirements, ensuring that the best image quality can be obtained in various complex situations, so as to maximize the extraction of effective information about the mold contour.

3. Spectral sensor module

The POMEAS SFS series of point spectral confocal sensors performs a key measurement task in this program. The sensor works based on the point spectral confocal principle and is capable of measuring the distance to the mold surface with high accuracy. With high measurement accuracy and repeatability, it is able to accurately determine the spatial position information of each point on the mold contour. Meanwhile, it has good adaptability to molds of different materials and surface characteristics, independent of color, gloss and other factors, and can be widely used in the contour scanning and measurement of molds made of various metals, plastics and other materials, providing accurate data support for the 3D contour reconstruction of molds.

4. Image measurement software

MetX Multi-sensor Measurement System, as the image measurement software platform of this program, has powerful functions and wide compatibility. It can be seamlessly connected with the above-mentioned optical lens module, spectral sensor module and other hardware devices to realize real-time data acquisition and transmission. The software not only processes and analyzes the data collected by POMEAS SFS series point spectrum confocal sensors, but is also compatible with a wide range of other types of measurement sensors, providing users with more diversified measurement options and more comprehensive measurement solutions. In terms of mold contour measurement, MetX software can quickly process the acquired image and point cloud data to realize a series of functions such as 2D dimension measurement, contour shape analysis and tolerance comparison. Through an intuitive user interface, operators can easily set up measurement tasks, view and analyze data, and generate detailed measurement reports, which greatly improves the work efficiency and data management level of mold contour scanning measurement.

Program Advantages

High-precision Measurement: The POMEAS 6.5X motorized zoom lens, five rings and eight zones ring light source and POMEAS SFS series point spectrum confocal sensor work together to achieve high-precision measurement of mold contour. Measurement accuracy in all dimensions can meet the strict requirements of the mold manufacturing industry for accuracy, effectively avoiding mold quality problems caused by measurement errors and improving product consistency and stability.

High adaptability: Whether it is a complex shape of the mold, or different material surface of the mold, the program has excellent adaptability. The flexible magnification adjustment of the motorized zoom lens, the multi-area illumination control of the ring light source, and the material-independent measurement principle of the point-spectrum confocal sensor enable the solution to cope with a wide range of mold profile scanning and measurement tasks, providing a versatile and reliable measurement solution for mold manufacturers.

Efficient workflow: The MetX multi-sensor measurement system optimizes the workflow of the mold profile scanning measurement. Everything from data acquisition to processing and analysis to report generation is automated. The operator only needs to simply set up the measurement task, and the software can automatically complete a series of subsequent operations, which greatly reduces the measurement time and improves the production efficiency. At the same time, the compatibility of the software makes it unnecessary to frequently change the equipment and software system when facing different measurement needs, further enhancing the work efficiency and convenience.

Comprehensive data analysis: Basic measurement of mold contours can be achieved, and in-depth analysis of the measurement data can also be carried out through MetX software. This includes accurate measurement and statistical analysis of 2D dimensions, fitting and deviation analysis of the contour shape, and tolerance comparison with the design model. These comprehensive data analysis functions help mold manufacturers to deeply understand the manufacturing quality of molds, discover potential problems in time and make optimization and improvement, so as to improve the overall quality of molds and production process level.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com