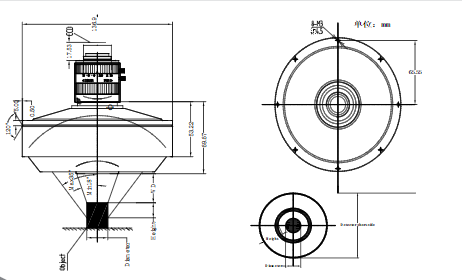

Principle of 360° external inspection lens

360 outer wall lens shows unique advantages in the field of small object inspection. It is mainly used in the imaging of small objects in the outer ring side view, through the advanced reflex system, can skillfully capture the image of the outer wall of the test object, and re-image it at the chip, and ultimately the perfect presentation of the image of the round crown.

Background of Cylindrical Inner Seal Inspection

Quality inspection of seals in cylindrical grooves is critical in many industrial production and manufacturing scenarios. The integrity, sealing and installation accuracy of the seal are directly related to the performance and reliability of the product. Traditional inspection methods often suffer from inefficiency, low accuracy, and difficulty in comprehensive inspection.

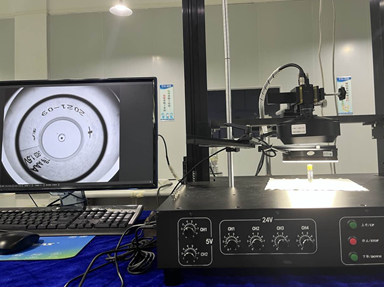

Cylindrical Internal Seal Inspection Program

Lens: 360 outer wall lens, its unique design is perfectly adapted to the inspection of seals in cylindrical grooves. Through the folding reflection system, the image of the outer wall of the seal can be captured in all directions, ensuring dead-angle-free inspection. At the same time, according to different diameters and heights of cylindrical objects, choose the appropriate lens parameters to obtain the best imaging effect.

Camera: 10 million industrial cameras are used in conjunction with 360 outer wall lenses. The industrial camera should have high resolution, high frame rate and good image stability, which can quickly and accurately capture the image information of the seal. Through the perfect combination with the lens to achieve high-definition imaging of the sealing ring, providing a high-quality data source for subsequent image analysis.

Visual light source: The ring light source plays a key role in the inspection process. It can provide uniform and stable illumination, effectively eliminate shadows and reflections, and make the image of the seal ring more clearly visible. According to different inspection environments and requirements, the brightness and angle of the ring light source are adjusted to ensure that the detailed features of the seal ring can be fully displayed.

Software: Advanced image analysis algorithm, real-time processing and analysis of the collected images, quickly and accurately determine the quality condition of the seal ring, providing reliable quality assurance for industrial production.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION