In the vast manufacturing field of electronic parts, aperture measurement is like a key screw, although small but significant, is a key link that many products can not be bypassed. Traditional aperture detection is often caught in the quagmire of cumbersome and inefficient, and the emergence of online size measuring instrument, like a ray of light, illuminating the new journey of aperture detection.

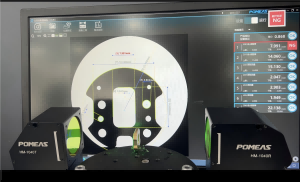

This compact in-line dimensional gauge is extremely easy to operate. The producer simply places the electronic part in the measuring area and the gauge quickly and accurately obtains the product's aperture dimensions thanks to its advanced sensing and calculation technology. The whole process is as smooth as running water, without the need for complex debugging and operation by specialized personnel, which greatly frees up manpower and improves the inspection efficiency on the production line.

Its powerful real-time monitoring function is even more remarkable. At the moment of measurement, the on-line size measuring instrument can clearly show whether the size of the round hole of the product is in accordance with the established standards, as if it is a rigorous quality guard, always sticking to the production line. This makes the quality control in the production process easy, and once there are unqualified products, they can be found and dealt with in a timely manner, effectively avoiding the waste of subsequent processes and the risk of defective products entering the market.

In addition, the in-line dimensional measuring instrument is also thoughtfully equipped with data export and history viewing functions. Production data can be exported in its entirety, providing a rich and reliable data base for quality analysis, process optimization and production management. Through the historical retrospective view, companies can analyze the trend of aperture size changes in the past production as if going through a photo album, pinpointing the root cause of potential quality problems, and then improve the production process to enhance product quality.

Especially worth mentioning is the overall compact design of the in-line dimensional measuring instrument. This feature allows it to be seamlessly embedded into the production line, like a precision gear, and fit perfectly into the entire production process. Products in the production of the first time, will be able to immediately accept the aperture size of the test, the real realization of the synchronization of production and testing, greatly reducing the production cycle, improve the production efficiency and market competitiveness of enterprises.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION