In the field of modern manufacturing and scientific research, high-precision measurement technology is the key to achieve product quality control, process optimization and in-depth exploration of scientific research. As a special optical element, telecentric lens plays an important role in improving measurement accuracy due to its unique imaging characteristics.

How telecentric lenses work

Telecentric lenses, as the name implies, are designed to allow light to enter the lens in a nearly parallel state and form a clear image on the imaging plane. Compared to conventional lenses, the most important feature of a telecentric lens is its “telecentric” characteristic, which means that the light passing near the center of the lens (the principal point) is nearly parallel to the optical axis of the lens, thus greatly reducing changes in image magnification and parallax effects due to changes in the position of the object or tilting. This feature enables telecentric lenses to provide more stable and consistent image quality in measurement applications, making them ideal for tasks such as precision measurement and 3D reconstruction.

Advantages of Telecentric Lens Measurement Accuracy

1, the elimination of parallax: telecentric lens telecentric design fundamentally eliminates the problem of parallax caused by changes in the distance between the object and the lens, to ensure that the measurement results are not affected by small changes in the position of the object.

2, high magnification stability: in different working distance, telecentric lens can maintain a relatively constant magnification, which is critical for applications that require accurate measurement of size and shape.

3, depth perception ability: Although telecentric lenses are mainly used for two-dimensional imaging, but through specific configurations and algorithms, they can also achieve accurate measurement of the depth of the object, suitable for three-dimensional measurement scenarios.

4, reduce light interference: due to its design to reduce the interference of stray light, telecentric lenses can still maintain good imaging quality under highly reflective or complex lighting conditions.

Factors affecting the accuracy of telecentric lens measurements

-

Lens quality: The manufacturing accuracy, material selection and coating quality of the lens directly affect the imaging quality and measurement accuracy.

-

Lighting conditions: uniform and stable lighting is the basis for ensuring measurement accuracy, insufficient or uneven light may lead to image blurring or edge detection errors.

-

Environmental vibration: External vibration will interfere with image stability and affect the repeatability of measurement results.

-

Image processing algorithms: Advanced image processing algorithms can extract edge information more accurately and improve measurement accuracy.

Telecentric lenses in practice

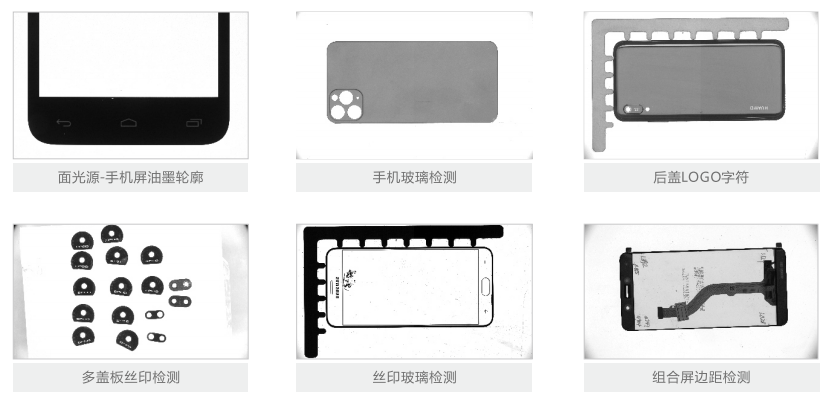

Telecentric lenses are widely used in semiconductor inspection, precision mechanical component measurement, biomedical imaging, and automated assembly line monitoring.

In the semiconductor manufacturing industry, telecentric lenses are able to accurately measure tiny feature sizes on chips to ensure that products meet strict quality standards; in the biomedical field, their high stability and low aberration imaging characteristics help in the fine observation and analysis of cells and tissues.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com