Functions and Roles of High Definition Industrial Lenses

The main function of HD industrial lenses is to capture image information from the production line and transmit this information to the image processing system for analysis and judgment. These lenses are equipped with high-precision image acquisition and processing capabilities to monitor various parameters of the product in real time, such as size, appearance, color, etc., to ensure that the product meets the quality standards.

High-definition industrial lenses enable every detail on the production line to be clearly presented through high-resolution and low-distortion image acquisition. This feature is especially important for production lines that require high-precision inspection, such as chip manufacturing and PCB board production.

Specific applications of high-definition industrial lenses in production lines

① Automated Inspection and Positioning

The combination of high-definition industrial lens and machine vision system can realize automated detection and positioning on the production line. In PCB board production, the lens can accurately recognize the position of the PCB board, component layout and other information, and help automated equipment to carry out precise welding, placement and other operations. This automated production greatly improves production efficiency, reduces manual intervention and lowers production costs.

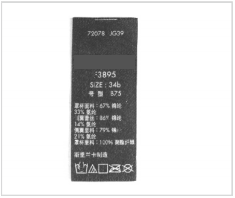

② Character Detection and Recognition

Character detection is an important task in automated production lines that involves recognizing and verifying characters on the product surface or packaging. With its high resolution and low distortion characteristics, HD industrial lenses are able to clearly capture character images, allowing even tiny characters to be accurately recognized. This function is particularly important in the field of chips, electronic products, etc., and plays a key role in product traceability and quality control.

③ Quality Inspection and Control

HD industrial lenses also play an important role in quality inspection and control. Through the image information captured by the lens, the size, appearance and other parameters of the product can be monitored in real time, and unqualified products can be detected and dealt with in a timely manner. This function helps to improve product quality, reduce scrap rate and improve customer satisfaction.

④ Data Acquisition and Analysis

HD industrial lenses can also be combined with image processing systems for data acquisition and analysis. Images captured by the lens can be extracted, analyzed and stored to help optimize the production process, improve efficiency and quality control. This feature provides strong support for production decision-making in enterprises.

Advantages of HD industrial lenses

POMEAS HD industrial lenses show significant advantages in automated production lines. It adopts advanced optical design technology, which can provide high resolution and low distortion images to ensure that characters are clearly presented in the image. At the same time, the lens has a wide range of adaptability to meet the needs of different types of character detection, adapting to different lighting conditions and shooting angles. In addition, the combination of POMEAS HD industrial lenses and high-speed industrial cameras enables efficient character detection and recognition, greatly improving the overall efficiency of production lines.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com