Multi-Million Industrial Lens Application: Metal Surface Texture Inspection

Metal Surface Texture Inspection Background

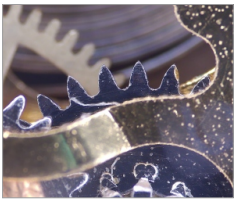

Metal surface textures not only affect the aesthetics of a product, but more importantly, they can reflect the processing quality, material properties, and potential defects of the metal material. For example, scratches, cracks or corrosion on metal surfaces can affect product life and safety performance. Therefore, accurate inspection of metal surface texture is a critical step in ensuring product quality and safety.

Multi-Million Industrial Lens Definition

Multi-Million Industrial Lens refers to industrial grade lenses with high resolution and premium imaging performance with a pixel level of 10 million.

Multi-Million Industrial Lens Features

1. High resolution: Capable of capturing fine grain and defects on the metal surface, ensuring the accuracy and reliability of the inspection.

2. Low distortion: Through precise optical design and manufacturing, it reduces the distortion of the image, making the inspection results more accurate.

3. Large aperture: Provides sufficient light intake to ensure good imaging results even in low-light environments.

4. Long focal length: able to magnify the details of the metal surface, making the inspection more accurate.

The application of ten million industrial lenses in metal surface texture detection

(1) Defect detection

Ten million industrial lenses are able to capture tiny scratches, cracks and corrosion and other defects on metal surfaces. Through image processing algorithms, these defects can be automatically identified, classified and recorded, thus realizing comprehensive monitoring of metal surface quality.

(2) Texture analysis

The texture characteristics of metal surfaces are important for product quality control. Ten million industrial lenses are able to capture the fine texture of metal surfaces and extract texture feature parameters, such as roughness and uniformity, through image analysis algorithms. These parameters can be used to assess the processing quality and material properties of the metal.

(3) Dimensional Measurement

In the metal manufacturing process, dimensional measurement is a critical step to ensure that the product meets the design requirements. The high resolution and precise imaging capability of multi-million industrial lenses makes dimensional measurement more accurate. Through image processing algorithms, dimensional parameters such as diameter, length and angle of metal surfaces can be automatically measured.

(4) Real-time monitoring

On the production line, the 10 million industrial lens can be used to monitor changes in the metal surface in real time. By continuously shooting and analyzing images, abnormalities on the metal surface, such as increased scratches and corrosion, can be detected in time, so that timely measures can be taken to avoid quality problems.

Advantages of multi-million industrial lens applications

-

highly accurate:The high resolution and precise imaging capabilities of multi-million dollar industrial lenses ensure accurate inspections.

-

high efficiency:Automated inspection processes greatly increase inspection speed and reduce labor costs.

-

comprehensive monitoring:It enables comprehensive monitoring of the quality of metal surfaces and ensures the consistency and stability of product quality.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com