In the field of precision measurement, POMEAS high-precision image measuring instrument stands out with its excellent performance, bringing a new measurement experience to many industries. Today, let's take a deeper look at the 5 core advantages of this measuring instrument.

I. Dual Camera Synergy, High Definition Detection

POMEAS high-precision image measuring instrument is equipped with a 2000w high-definition camera, combined with advanced edge detection algorithms, which can realize the automatic measurement of surface light. This combination makes the measuring instrument like having a pair of sharp eyes, able to accurately capture every detail of the object surface. In the production of electronic components, for the size measurement of tiny chips, its dual-camera system can clearly present the edge contour of the chip, through the algorithm to quickly and accurately measure the chip's dimensional parameters, to ensure that the product quality meets the standards.

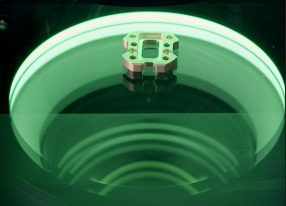

II. Dual-side telecentric lens, ultra-low distortion

dual-side telecentric lens is a major highlight of this measuring instrument. Its ultra-low distortion characteristics, even in the face of a segment difference and edge position of the object, the field of view graphics will not be deformed. This means that there is no need to worry about deviations in measurement results due to lens distortion, regardless of the complex shape or position of the object being measured. In the precision measurement of automotive parts, for some irregularly shaped parts, the double-sided telecentric lens can always maintain accurate imaging, providing reliable data support for quality inspection.

III. Adjustable light source, intelligent adaptation

The Image Measuring Instrument has a built-in brightness sensor that automatically adjusts the light according to the measuring environment and object material to achieve the best visual effect. This feature greatly improves the accuracy and stability of the measurement. In the jewelry appraisal industry, gemstones made of different materials have different light reflection and absorption characteristics. The adjustable light source can automatically match the most suitable lighting conditions for different gemstones, clearly displaying the internal texture and imperfections of the gemstones, and helping appraisers make accurate judgments.

IV. Stable large-scale load mobile platform, wide measurement range

The image measuring machine is equipped with a stable and large moving platform with a measuring range of 300mm * 200mm * 75mm, which enables it to adapt to a wide range of sizes and types of objects to be measured. In the mold manufacturing industry, the size inspection of large molds has always been a difficult problem, and POMEAS high-precision image measuring instrument with its wide loading platform, can easily cope with, for the production of molds and mold quality control to provide a strong guarantee.

V. One-key quick measurement, efficient and convenient

The ease of operation is also one of the key advantages of this measuring instrument. The measurement process can be completed with just one keystroke. In the inspection of mass-produced products, the operator can quickly complete the measurement of multiple products, which greatly improves the inspection efficiency. For example, in the production line of plastic products, workers can quickly obtain the dimensional data of the products through one-button operation, and timely detection of unqualified products, which effectively improves production efficiency and product quality.

These 5 advantages of POMEAS high-precision image measuring instruments make them play a key role in many industries such as electronics, automotive, jewelry, and mold making.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com