Industrial Lens: Unlocking the Dual Vision of Industrial Micro and Macro

In the precision operation of modern industry, industrial lens as a key component of machine vision system is bringing all-round changes to industrial production with its unique performance. It is not only able to penetrate into the micro world, insight into the subtleties of the product, but also from a macro perspective to control the entire production process, as if for the industrial field to give a pair of both micro-insight and macro-control capabilities of the “wisdom of the eye”.

Working Principle

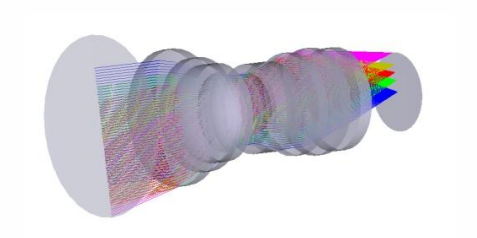

The working principle of industrial lenses is based on optical imaging technology. Light passes through the optical elements of the lens, and after a series of processes such as refraction and focusing, the image of the photographed object is clearly projected onto the image sensor. The optical design of the lens determines its imaging quality, including resolution, contrast, color reproduction and other key indicators. High-quality industrial lenses can minimize aberration and chromatic aberration to ensure that the captured image is accurate and clear, providing a reliable data base for subsequent analysis and processing.

Microvision: Insight into the Subtle Mysteries of Industrial Parts

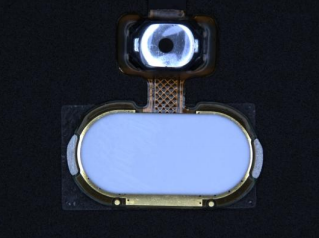

At the microscopic level, industrial lenses, with their high magnification and excellent resolution, have become “quality detectors” in industrial manufacturing. Taking semiconductor manufacturing as an example, the manufacturing process of chips has entered the nanometer level, and their internal lines and components are extremely tiny. Industrial lenses are able to clearly present the minute lines on the chip and detect even extremely small defects, such as short circuits, broken circuits or incomplete etching. This is critical to ensure the performance and reliability of the chip, any one of the smallest defects may lead to the failure of the chip function.

In the field of precision machining, industrial lenses also play an irreplaceable role. For precision gears, bearings and other parts, the surface of the microscopic texture and dimensional accuracy directly affects the mechanical performance and life. Industrial lenses can clearly observe the machining marks on the surface of the parts, roughness, etc., to help engineers determine whether the processing process is up to standard. Through the control of microscopic details, manufacturers can continuously optimize the production process, improve product quality and meet the stringent requirements of high-end manufacturing for precision parts.

Macro View: Getting a global view of the production process

From a macro perspective, industrial lenses can provide enterprise managers with comprehensive production information to help scientific decision-making. In the operation of large-scale production equipment monitoring, industrial lenses can real-time monitoring of the operational status of the equipment, such as the operation of the conveyor belt, the accuracy of the movement of the mechanical arm and so on. By analyzing this information, managers can identify potential faults in a timely manner, carry out maintenance in advance to avoid production standstill due to equipment failure, thus improving production efficiency and equipment life.

POMEAS, as a professional brand in the field of industrial lenses, has been committed to developing and producing high quality industrial lenses. Our products cover a wide range of application scenarios from appearance inspection to dimensional measurement, and provide strong support for industrial production in various industries with excellent optical performance and stable and reliable quality.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com