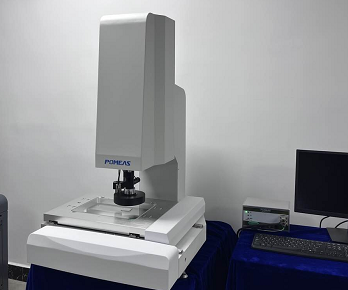

In the production of camera modules, the key to ensuring product quality and performance is accurate inspection. 3D Profilers are the ideal tool for camera module inspection because of their excellent inspection capabilities.

Test content

POMEAS 3D Profiler detects all kinds of defects in camera modules. Marks such as scratches and scuffs may affect the light transmission and imaging effect, while foreign objects and contamination may lead to image anomalies and affect the picture quality. Defects such as indentation and white spots should not be ignored, as they will directly affect the performance and service life of the camera module.

Height difference detection is one of the important functions of POMEAS 3D Profiler. By accurately measuring the height difference between different parts of the camera module, it ensures the accuracy of its installation. This is essential to ensure the stability and reliability of the camera module.

Gluing inspection is also an advantage of POMEAS 3D Profiler. During the production of a camera module, the quality of the glue application directly affects the sealing and waterproof performance of the product. POMEAS 3D contouring system can accurately detect the thickness and uniformity of adhesive coating to ensure that the quality of adhesive coating meets the standard.

Advantage of testing equipment

The POMEAS 3D Profiler is equipped with advanced optical modules, including a 6.5X zoom lens that enables fast focusing to capture the details of the camera module. The Spot Spectral Sensor Module provides high precision inspection capabilities to ensure accurate results.

The MetX measurement software works perfectly with the POMEAS 3D Profiler for easy operation. Through the software's interface, users can easily perform inspection and data processing.

Application Scenarios

On the production line of camera modules, POMEAS 3D Profiler can quickly detect defects and provide timely feedback for quality control. It can inspect all aspects of the production process to ensure product quality is up to standard.

In the product development phase, POMEAS 3D Contouring can help R&D staff to better understand the performance and characteristics of the camera module, providing a basis for product improvement.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION