In today's rapid development of science and technology, online digital rangefinders are quietly changing the production and inspection methods of many industries with their excellent performance and wide range of applications. From the precision processing of industrial manufacturing to the accurate measurement of construction projects, from the micro-world of electronics and semiconductors to the macroscopic field of automobile manufacturing, online digital rangefinders are everywhere. With advanced technology and powerful functions, it provides efficient and accurate measurement solutions for various industries, and has become an important force to promote the development of the industry.

Industrial Manufacturing:

① Wire and cable industry: real-time monitoring of the outer diameter of the wire and cable, to ensure that the product meets the standard specifications, to improve the consistency and reliability of the product, and to help the enterprise to timely find out the dimensional deviation in the production process, to avoid waste and the generation of defective products.

② Machinery manufacturing field: accurate measurement of various shafts, holes and parts of the size, to provide strong support for the precision control of the machining process, to help ensure the interchangeability of parts and the overall performance of the equipment.

③ Plastic pipe production: rapid detection of the wall thickness and diameter of the pipe, to help companies optimize the production process, according to the results of the measurement of timely adjustment of production parameters, improve product quality and reduce the loss caused by unqualified dimensions.

Electronics and Semiconductors:

① Electronic component manufacturing: Accurately measure the dimensions of electronic components, such as the edge length of the chip, the spacing of the pins, etc., to ensure that the components comply with high-precision quality standards, and to safeguard the performance and stability of electronic products.

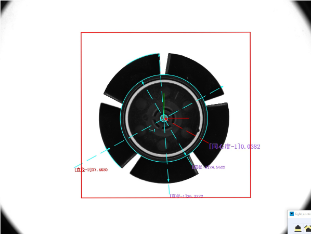

② Semiconductor production: In the process of semiconductor manufacturing, the dimensions of silicon wafers and the spacing of photolithographic patterns are precisely measured to provide key data for the control and optimization of the semiconductor process.

Automotive Manufacturing:

① Parts Inspection: Measure the dimensions of automobile parts, such as the bore diameter of the engine block, the diameter of the crankshaft, the thickness of the body sheet, etc., to ensure the quality and assembly precision of the parts and improve the overall performance and safety of the automobile.

② Automobile assembly: In the process of automobile assembly, it is used to detect the gap and fit size between parts to ensure the assembly quality and avoid the problems of rattling and leakage caused by the size problem.

Aerospace:

① Component manufacturing: high-precision measurement of the dimensions of aerospace components, such as the dimensions of aircraft engine blades, the thickness of wing structural components, etc., to ensure the performance and reliability of components under extreme conditions.

② Vehicle assembly: during the assembly process of the vehicle, precisely measure the installation position and clearance of each component to ensure the aerodynamic performance and overall structural strength of the vehicle.

Medical field:

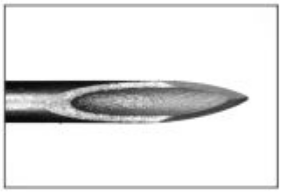

① Medical Device Manufacturing: Measure the key dimensions of medical devices, such as the diameter of syringe tubes and the length of scalpel blades, etc., to ensure the precision and safety of medical devices and meet the strict requirements of the medical industry for product quality.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com