Have you chosen the right visual light source for your inspection program?

In the inspection program, the choice of vision light source is crucial. It not only determines the accuracy and efficiency of inspection, but also directly affects the performance and stability of the system. The following will discuss in detail the types of visual light source, selection program and its application in various industries.

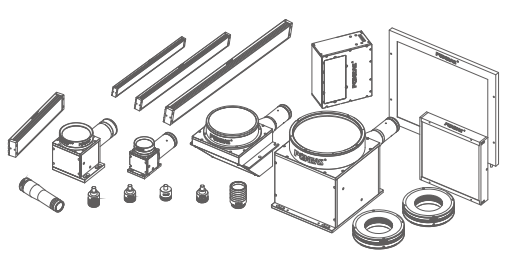

There are many types of vision light sources, including but not limited to bar light sources, flat light sources, point light sources, etc.. These light sources can be based on the actual needs of a variety of combinations, in order to illuminate every corner of the inspected product, to ensure that the inspection process is carried out smoothly.

1, strip light source: usually used for larger square structure of the test object lighting. The color can be matched according to the needs of free combination; irradiation angle and installation of arbitrarily adjustable. Strip light source in the metal surface inspection, image scanning, surface crack detection and LCD panel inspection and other fields have a wide range of applications.

2, plane light source: to provide no diagonal irradiation shadow problem, a variety of colors can be selected. LED high-density arrangement, local and overall uniformity. Plane light source in the measurement of the size of mechanical parts, electronic components and IC shape detection, film smudge detection and transparent object scratch detection and other aspects of outstanding performance.

3, point light source: high-power LED, small size, high luminous intensity. Point light source is a fiber-optic halogen lamp alternatives, especially suitable for coaxial light source as a lens, etc.. Efficient heat sink greatly improves the service life of the light source. Point light source is suitable for telecentric lens use, such as chip detection, mark point positioning and wafer and liquid crystal glass substrate correction.

Vision light source type selection program

1. Check the dimensions of the target and installation conditions: in order to determine the shape and size of the light source unit. For example, for inspection in a small space, it may be necessary to select a smaller point or ring light source.

2. Check the material and color of the target and background: to determine the color (wavelength) of the light source. Different materials and colors of objects have different absorption and reflection characteristics of light, so you need to choose the most suitable light source color according to the actual situation.

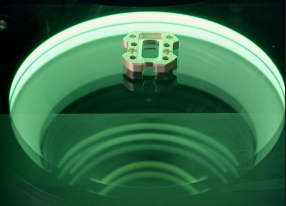

3. uniformity and stability of the light source: for demanding inspection tasks, you need to choose a better uniformity and stability of the light source, such as the same as the axial light source or ring light source.

4. Adjustable light source: some inspection tasks may need to adjust the brightness and angle of the light source according to the actual needs, so the choice of adjustable light source will be more flexible and convenient.

Industries where vision light sources are used

1. Industrial automation: In the inspection process of small parts, the ring light source can highlight the contour characteristics of the object, so that the inspection equipment can accurately identify the small defects of the parts, such as scratches, breakage and so on. Strip light source is suitable for the detection of long objects, such as metal pipe surface defect detection.

2. Machine vision system: the core of machine vision system is image acquisition and processing, and the light source is the key factor affecting the imaging quality. Coaxial light source is widely used for surface imaging inspection of semiconductors, PCB boards and metal parts due to its high uniformity and good optical effect. High-bright strip light source can ensure that every detail of the circuit board is clearly illuminated, so that the inspection equipment can accurately identify the circuit board defects.

3. Medical imaging: medical imaging equipment requires light sources that can not only provide pure light to avoid interference with human tissue imaging, but also in different imaging modes to provide appropriate auxiliary lighting. Bright and uniform surface light source can provide stable illumination, so that doctors can clearly observe the teeth and oral tissues of the fine structure.

4. Logistics and warehousing: automated sorting equipment can not be separated from the support of multi-functional vision light source. It can be flexibly adjusted according to the size, shape and location of the package to ensure that the bar code or identification labels are clearly illuminated, thereby improving the accuracy and efficiency of sorting.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com