Image Dimensioning: Reinventing the Watch Case Dimension Inspection Standard

In the field of fine watchmaking, a watch is not only a precision instrument to record time, but also a masterpiece of art, design and exquisite craftsmanship on the wrist. From the delicate sculpture of the dial to the fine texture of the strap, every detail has been repeatedly polished by watchmakers. Among them, the precise control of the dimensions of the watch's outer contour is like the cornerstone of a tall building, which is directly related to the wearing comfort, overall aesthetics and functional realization of the watch.

For a long time, the traditional measurement means in the face of the outer contour of the watch such a complex and extremely high precision requirements of the object, exposed a number of shortcomings. Manual caliper measurement is susceptible to the influence of the measuring personnel's technique and eyesight, and the slightest hand tremor or visual deviation may lead to data inaccuracy; although the CMM has high precision, its operation is complicated and time-consuming, which makes it difficult to satisfy the demand for rapid sampling inspection on efficient production lines.

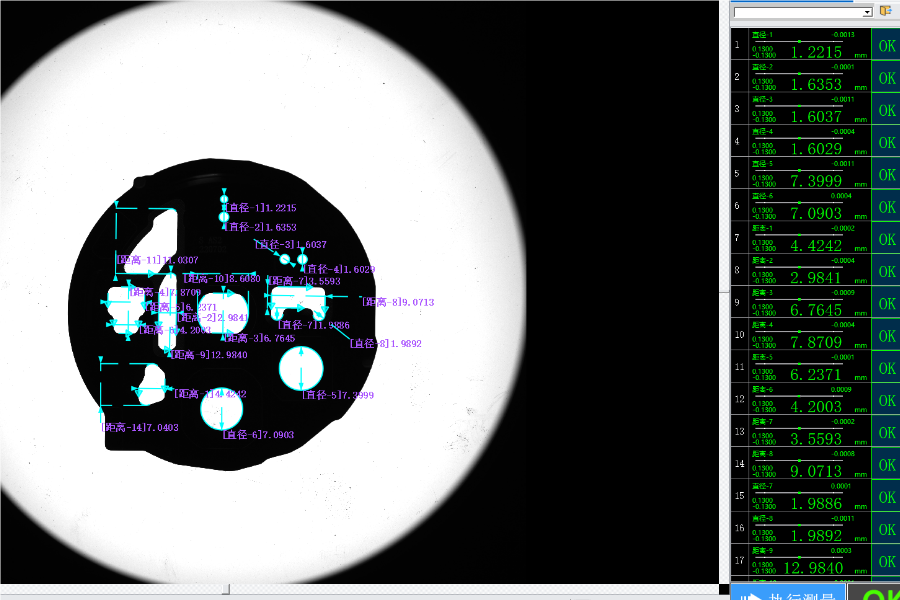

Example of Image Dimension Measuring Instrument

The POMEAS Image Dimensioner utilizes a superior optical imaging system to present the complex outer contours of a watch case as an ultra-high resolution digital image on the screen. The operator simply sets the measurement parameters on the accompanying software and, with a single click, quickly obtains dozens of key dimensions such as case diameter, thickness, and bracelet attachment width.

Image Dimension Gauge Advantages Showcased

1. Micron-scale accuracy: POMEAS image size measuring instrument is equipped with cutting-edge optical lens and high-precision image sensor, with amazing micron-level measurement accuracy. Whether it is the hair-thin polished chamfers on the edges of the watch case, or the subtle gap changes at the interface between the dial and the case, they can all be precisely quantified to ensure that the dimensional error of each piece of watch case is controlled within a very small range, which provides a solid data guarantee for the high-end watchmaking process.

2. Super adaptability and multi-functional measurement: POMEAS is capable of measuring a wide variety of watch cases, from classic round and square to polygonal and shaped structures with strong personality. It can not only accurately measure straight line distance and various parameters of circle, but also accurately fit complex irregular curves and surfaces through intelligent algorithms, which meets the all-around dimensional measurement needs in the watch manufacturing process.

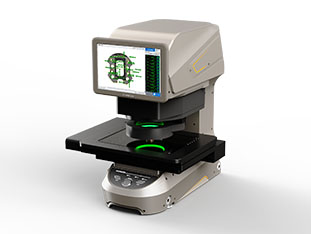

3. Efficient and convenient operation experience: Abandoning the cumbersome operation process of traditional measuring tools, POMEAS Image Dimension Measuring Instrument adopts an intuitive and simple human-computer interaction interface. Measuring personnel can quickly get started without long professional training. Simply place the watch case on the measurement platform, and through the software guidance, all the key dimensions of the measurement and data recording can be completed in just a few minutes, which greatly improves the inspection efficiency on the production line.

4. Intelligent data management and traceability: After completing the measurement, the powerful data processing capability of POMEAS measuring instrument can be highlighted. It can automatically generate a detailed measurement report, including size data, measurement time, operator and other key information, which is convenient for subsequent quality control and problem tracing.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com