In today's era of rapid development of science and technology, the manufacturing process of semiconductor chips is becoming more and more delicate and complex, which puts forward extremely high requirements for the observation and inspection technology of microchips. As an advanced observation tool, the motorized zoom auto-focus microscope provides strong support for the research and production of microchips.

Working Principle of Motorized Zoom Autofocus Microscope

The motorized zoom auto-focus microscope is mainly composed of four parts: four-zone light source, motorized zoom lens, auto-focus system and control system.

① The four-zone light source provides uniform, bright and adjustable illumination to ensure that the chip can obtain clear images at different magnifications.

② The motorized zoom lens drives the zoom lens group through an electric motor to achieve fast and precise adjustment of the focal length, thus changing the zoom-in or zoom-out ratio of the image.

③ The autofocus system has a built-in high-precision sensor and advanced algorithms to detect the clarity of the chip surface in real time and automatically adjust the focus to ensure that the image is always clear and sharp.

④ The control system is responsible for receiving user commands and controlling the operation of the electric motor and autofocus system to realize the precise control of the microscope.

The need for microchip observations:

With the continuous progress of semiconductor technology, the size of the chip is getting smaller and smaller, and the structure is getting more and more complex. In the process of chip design, manufacturing and quality inspection, the microstructure, circuit wiring, transistor performance, etc. of the chip need to be accurately observed and analyzed. Traditional microscopes have certain limitations in magnification, focusing accuracy, ease of operation, etc., which make it difficult to meet the high requirements of microscopic chip observation. The motorized zoom auto-focus microscope can quickly and accurately adjust the magnification and focus to provide clear and stable images, providing an ideal solution for microchip observation.

Advantages of motorized zoom autofocus microscopy in microchip observation

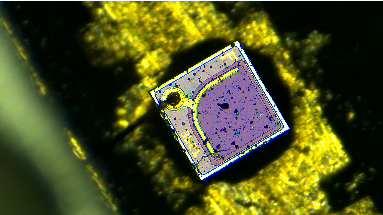

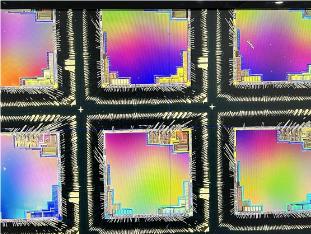

1. High-resolution imaging: The microscope can provide high-resolution images, allowing researchers to clearly observe the microstructure of the chip, such as the size, shape and arrangement of the transistors, as well as the details of the circuit wiring, etc., which can help to discover potential defects and problems.

2. Fast zoom and focus: Motorized zoom and auto-focus functions can greatly improve observation efficiency. Researchers only need to input commands through the control system, and the microscope can be quickly adjusted to the required magnification and focus position without manual adjustment, saving time and energy.

3. Accurate measurement and analysis: Combined with the professional measurement software, it can accurately measure and analyze the size, pitch, angle and other parameters of the chip, providing accurate data support for the design and manufacture of the chip.

4. Non-contact observation: adopting non-contact observation mode, avoiding damage to the chip surface and ensuring that the integrity and performance of the chip are not affected.

5. Adaptation to different chip sizes and types: By adjusting the magnification and working distance, the microscope can adapt to the observation needs of different chip sizes and types, with strong versatility and flexibility.

Chip practical application

1 、Chip design verification: In the chip design stage, researchers need to repeatedly observe and verify the prototype of the chip to ensure the rationality and feasibility of the design. The motorized zoom auto-focus microscope can help them observe the microstructure and performance of the chip quickly and accurately, discover and modify the problems in the design in time, and shorten the development cycle of the chip.

2、Chip manufacturing process inspection: In the process of chip manufacturing, it is necessary to carry out strict quality inspection for each process to ensure the quality and performance of the chip. The microscope can be used to detect scratches, pollution, lithographic defects and other problems on the chip surface, timely detection and elimination of defective products, improve the yield of the chip.

3、Chip failure analysis: When the chip malfunction or failure, it needs to be analyzed to find out the cause of failure and take corresponding measures. Electric zoom auto-focus microscope can help engineers observe the internal structure of the chip and the circuit connection, look for possible failure points, and provide a basis for the repair and improvement of the chip.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com