Background on Artificial Skeletal Measurements

Artificial bone, as an advanced medical implant, is widely used in surgeries such as fracture repair and joint replacement. In order to ensure the precise matching of artificial bones and the success of surgery, accurate measurement of their dimensions is crucial. Traditional measurement methods, such as contact measurement (e.g., vernier calipers, etc.), are simple to operate but may have measurement errors and are not suitable for 3D measurement of complex shapes. Therefore, non-contact 3D measurement methods are gradually favored, among which the image dimension meter, as a high-precision, non-contact measurement tool, shows great potential in the measurement of artificial bone dimensions.

Application of Image Dimension Measuring Instrument in Artificial Bone Measurement

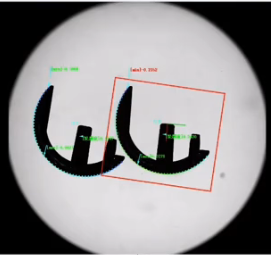

(1)Quick measurement of flat surfaces

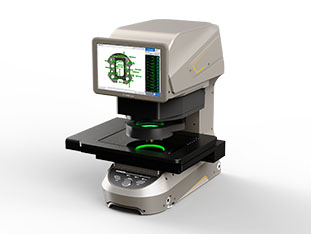

The Image Dimension Measuring Instrument utilizes advanced image acquisition and processing technology to quickly and accurately measure the planar dimensions of artificial bones. With a high-precision image sensor and image processing algorithms, the instrument is able to capture the minute details of the bone surface and perform precise calculations to obtain the flat dimensional data of the bone. This measurement method not only improves the measurement efficiency, but also reduces human error, providing doctors with reliable dimensional information.

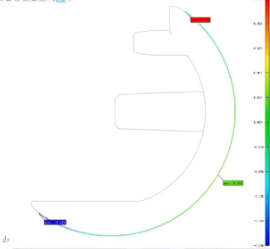

(2)Scanning 3D contours

In addition to planar dimensioning, the Image Dimensioner is capable of scanning the 3D contours of artificial bones. Through image acquisition from multiple angles and 3D reconstruction algorithms, the instrument is able to generate a 3D model of the bone and accurately measure its 3D dimensions. This 3D measurement technology is important for evaluating the shape and size of bones as well as the fit of implants. Based on the 3D model, the surgeon can visualize the structure and characteristics of the bone more intuitively and thus make a more accurate surgical plan.

(3)Measurement of flatness and height

Flatness and height measurements are equally important in artificial bone dimensioning. Image Dimensioning Instruments are able to accurately measure flatness and height variations of bone surfaces through high-precision image processing and algorithms. This is critical for assessing the flatness of the bone and the stability of the implant. By measuring flatness and height, the surgeon can determine if the bone needs to be trimmed or treated to ensure implant stability and surgical success.

The Image Dimensioner offers significant advantages in artificial bone dimensioning. Its fast, accurate, non-contact measurement provides physicians with reliable dimensional information, which helps to develop more accurate surgical plans and improve surgical success.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com