Simultaneous Measurement of Multiple Specifications-Online Image Measuring Instrument

In manufacturing, accurate and efficient dimensional measurements are key to ensuring product quality and productivity. However, traditional measurement equipment often faces a challenge: when a measurement program is turned on, it can usually only measure for one size of product. This means that when a production line needs to measure multiple product sizes, the measurement equipment may need to change measurement programs or make manual adjustments frequently, which not only reduces productivity but also increases the risk of errors.

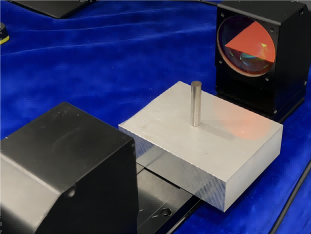

In order to solve this challenge, POMEAS In-Line Image Gauge has undergone a major technological update to achieve compatibility with multiple programs for simultaneous measurement. This innovative breakthrough enables POMEAS In-Line Image Measuring Instruments to accurately measure multiple product sizes in the same time period, greatly increasing flexibility and productivity in the measurement shop.

The POMEAS in-line image measuring instrument owes this capability to its advanced image recognition and processing technology. Through high-precision image capture and intelligent analysis algorithms, the gauge is able to accurately identify and locate products with different specifications, while running the corresponding measurement program for precise measurement. This not only avoids the problems of wrong positioning capture or unqualified NG that may occur when changing the measurement program of traditional measurement equipment, but also significantly improves the accuracy and stability of measurement.

Advantage of simultaneous measurement function of multiple specifications:

1、Improve production efficiency: no need to frequently change the measurement program or make manual adjustments, greatly reducing the measurement time and improving the overall efficiency of the production line.

2、Reduce the error rate: through intelligent identification and precise measurement, it reduces the errors caused by human operation and improves the accuracy and reliability of measurement.

3、Enhance flexibility: able to cope with the measurement needs of products with multiple specifications, making the production line more flexible and diversified.

4、Optimize the allocation of resources: reduce the additional equipment and human resources required for frequent replacement of measurement procedures, reducing production costs.

In-line image measuring instrument multi-specification simultaneous measurement function solves the challenges faced by traditional measuring equipment in measuring products with multiple specifications, improving productivity, reducing error rates, enhancing flexibility and optimizing resource allocation provides strong support.

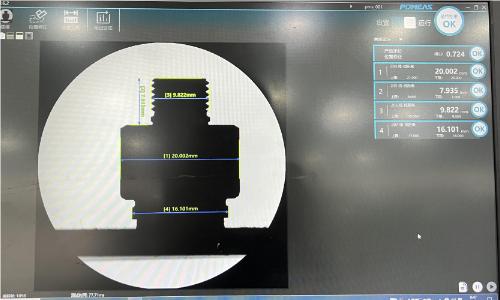

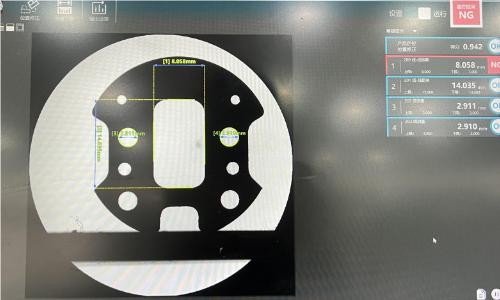

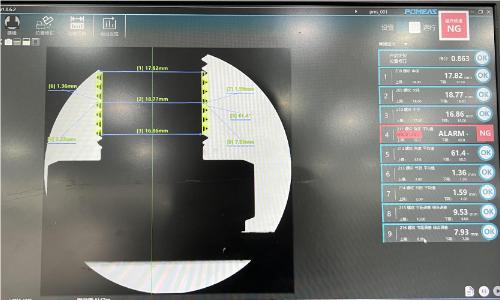

Case presentation:

Results Showcase:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com