Application of Image Dimension Measuring Instrument in Metal Products Inspection

In modern industrial production, accurate and efficient inspection means are crucial to ensure product quality. Especially in the production process of metal products, the accurate detection of product dimensions, characters, two-dimensional codes and other information can greatly improve the product qualification rate and production efficiency. As a kind of advanced inspection equipment, image size measuring instrument is gradually showing its unique advantages in the field of inspection of metal products.

Detection of product characters and QR codes

On production lines for metal products, it is often necessary to print characters or 2D codes on products for traceability and identification. The Image Dimension Measuring Instrument is able to utilize advanced image processing technology to quickly and accurately identify and detect these characters and 2D codes. This not only ensures accurate information about the product, but also greatly improves the automation of the production line and reduces the cost and error of manual inspection.

Measuring metalwork brushes

For brushes in metal products, their length, width and other dimensional parameters are important indicators of their quality. The Image Dimension Measuring Instrument is able to accurately measure the length and width of brushes by capturing and processing the image of the brushes. This non-contact measurement method not only avoids the wear and tear and errors that may be associated with traditional measuring tools, but also improves the efficiency and accuracy of the measurement.

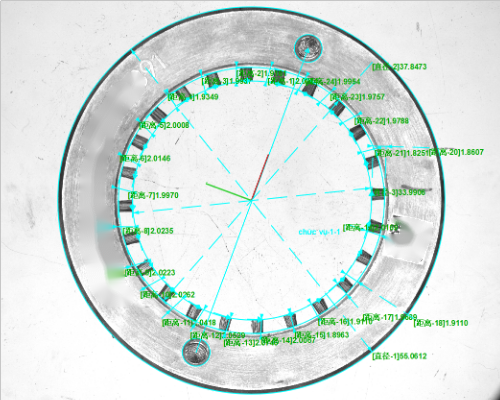

Measuring the distance between metal brushes

In the production of metal products, the spacing between metal brushes often has a significant impact on the performance and effectiveness of the product. The Image Dimension Measuring Instrument can accurately measure the spacing between metal brushes by precisely analyzing the image of the metal brushes. This high-precision measurement method helps to detect deviations in production in a timely manner, ensuring the stability and consistency of product quality.

Test Results:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION