In the complex process of industrial production and quality control, lighting source is not simply a “bright” tool, it is often a key factor in determining the accuracy and efficiency of detection. Today, we will explore the bar light source, see how it is with unique advantages, play a key role in many areas, to become the engineers in the hands of the right “eye”.

Packaging industry: guarding the first line of defense for products

Packaging as a product “coat”, its integrity is directly related to product quality and storage and transportation safety. Strip light source in this field to make a big difference, thanks to its large luminous angle and uniform light characteristics. When the various types of packaging for testing, whether it is paper boxes, plastic bags, or glass bottles labeling package, the light can be all-round, dead-end coverage.

Imagine, in the food packaging assembly line, the slightest crack in the packaging may lead to food spoilage by moisture; pharmaceutical packaging, if broken, the safety and effectiveness of drugs will be threatened. Strip light source evenly spread the light, so that the naked eye is difficult to detect the damage, in the imaging system presents a clear contrast between light and dark, as to the inspector put on a pair of “X-ray perspective glasses”, accurately identify the location of the damage, to ensure that only well-packaged products can flow to the market.

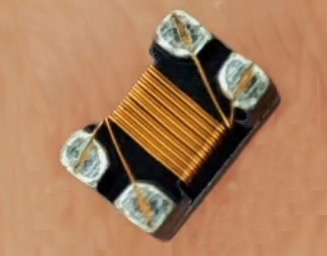

Electronics Manufacturing: The Light of Precision in Sculpting Microcosms

The manufacture of electronic components is a field that requires a high degree of precision, and strip light sources play an indispensable role here. Taking liquid crystal components as an example, the complex arrangement of liquid crystal molecules inside them determines the display effect of the display. The light emitted by the strip light source is able to penetrate the liquid crystal layer at an appropriate angle, illuminating every subtle area uniformly.

During the inspection process, R&D personnel can observe the imaging of the liquid crystal components under the illumination of the strip light source, and quickly discover abnormal molecular arrangement, pixel defects and other problems, so as to nip defective products in the bud. Similarly, for LCD character display inspection, to ensure that each character stroke is complete and the clarity is up to standard, the stable illumination provided by the strip light source, together with the high-precision imaging equipment, can accurately locate and mark possible defects such as missing strokes and fuzzy characters, so as to safeguard the user experience of electronic products.

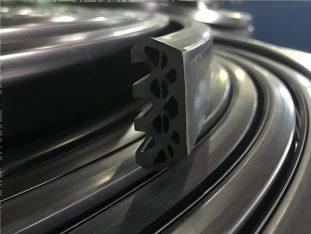

Machine building and automotive industry: defending perfect surfaces for large workpieces

Large parts for machinery manufacturing, automobile bodies and components, etc., all need to ensure that the surface quality meets extremely high standards. Even small scratches on the surface of large objects not only affect the aesthetics, but also may cause stress concentration, corrosion and other problems in subsequent use.

Strip light source by virtue of a large area of uniform illumination, these large workpieces for “carpet” scanning. For example, automobile body painting before the inspection link, the light can make the small scratches have nothing to hide, the staff can be repaired in advance, to avoid defective vehicles factory. In the machinery manufacturing workshop, large steel plates, castings and other surface quality monitoring, strip light source is also a credit, through the uniformity of light to reduce reflective interference, a clear presentation of scratches, sand holes and other defects, in order to create a high-quality mechanical products to lay the foundation.

Fine material testing: no tiny hidden dangers are spared

Strip light sources also play an amazing role in some seemingly insignificant but vital materials inspection scenarios. For example, masking tape, which is often used for temporary protection during the assembly of electronic devices, automobile manufacturing, etc., if broken, it may lead to contamination or damage to the parts underneath the tape. Strip light sources make the irregular contours of the tape's torn edges readily apparent in the imaging through subtle illumination.

Functional materials such as expanding and stretching films play a role in expanding and stretching under specific environments to ensure the structural stability of a product or to realize special functions. Once broken, the risk of functional failure increases dramatically. Strip light source with professional inspection equipment accurately captures the tiny breakage points on the film to ensure that they can properly “perform their duties” at critical moments.

Electronic Connector Inspection: Guaranteeing Unobstructed Signal Transmission

As a key interface in electronic equipment and electrical systems, the pin flatness of connectors directly affects the stability of signal transmission. Even the slightest difference in pin height may lead to data loss, equipment failure and other serious consequences during high-speed signal transmission.

The strip light source creates an ideal environment for connector pin inspection with multi-angle, large field of view illumination. Under the uniform coverage of light, the pin flatness difference is transformed into clearly distinguishable light and shadow changes, the inspector with the help of simple visual tools or automated inspection system, can quickly determine whether the pin is qualified, for the reliable operation of electronic systems escort.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com