In today's industrial manufacturing and inspection world, where high precision and efficiency are sought after, the choice of lighting source plays a pivotal role. POMEAS, as a leader in the industry, has carefully crafted strip light sources with excellent characteristics to provide the ideal light for many complex inspection tasks.

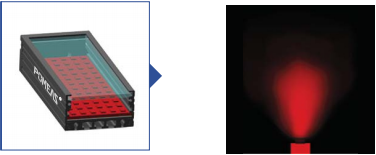

Excellent luminous properties: large angle, more uniformity

The bar light source breaks new ground by utilizing large angle SMD LEDs, which is a brilliant design. Compared with traditional light sources, its light-emitting angle has been greatly expanded, and the light, like the soft and widely spread daylight in the morning, can evenly cover a large area. Whether it is a wide plane, or a three-dimensional object with a certain depth, can be bathed in this balanced light. This uniformity effectively avoids imaging shadows and reflective defects caused by uneven light and darkness, and ensures that every subtle feature can be clearly and realistically rendered within a large field of view, providing stable and reliable illumination for medium- and high-angle illumination needs.

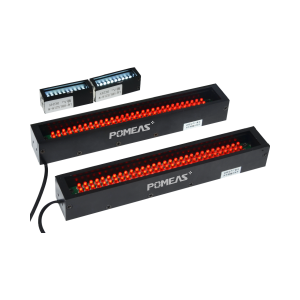

Tailored dimensions: free adaptation from millimeters to meters

POMEAS strip light sources show remarkable flexibility when it comes to inspecting objects of different sizes. They are available in a wide range of lengths, from a few millimeters to meters. In the electronic chip microscopic line detection, short and compact strip light source can be focused on the square inches, accurately illuminating those hair-thin lines; and when faced with car body panels, large displays and other huge workpieces, the ultra-long size of the strip light source can be a complete coverage, not to miss any macro defects, to really do a million changes to respond to the changes, to meet each of your practical application scenarios.

Colorful light, precise choice

We understand that different inspection targets have unique light color preferences. POMEAS strip light source provides a wide range of light color options, you can choose the most suitable light according to the object material, surface texture and desired features. Red light is highly penetrating and can help penetrate translucent materials to reveal hidden defects, while blue light has the ability to enhance the contrast between minor scratches and flatness differences when inspecting metal surfaces, making defects invisible. Such a diverse color library gives you unlimited possibilities to customize your own lighting solutions.

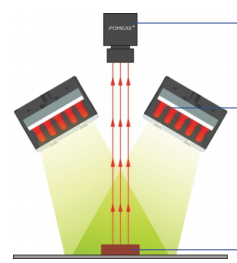

Combine and angle as you wish

A single strip light source is already powerful, but multiple strip light sources working together are even more powerful. POMEAS takes into account the diverse needs of complex inspection tasks and allows multiple light sources to be combined like building blocks. According to the shape of the workpiece and the focus area of the inspection, you can flexibly put together the layout to build an omni-directional, dead-angle-free lighting matrix. Moreover, the irradiation angle of each strip light source can be independently fine-tuned, from vertical overhead to tilted side illumination, precisely adjusted to the most suitable angle for the inspection of difficult points, to ensure that the light, like intelligent navigation, directly hit the key parts of the target, and remove all the obstacles of light and shadow for your visual inspection system.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com