In the field of industrial vision inspection, lenses are the key components for capturing high-quality images. Standard industrial lenses excel in most routine scenarios due to their versatility and cost-effectiveness. However, when confronting complex inspection tasks demanding extreme precision and sensitivity to geometric distortion, telecentric lenses demonstrate irreplaceable advantages through their unique optical properties.

1. Dimension Measurement of Thick Objects

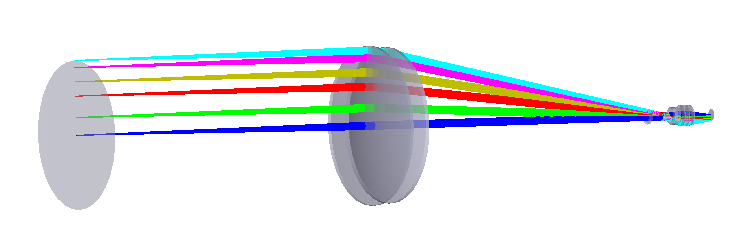

In manufacturing, precise dimension measurement of objects with significant thickness—such as metal sheets and plastic parts—is a common requirement. When capturing such objects with standard industrial lenses, the perspective distortion effect causes image distortion at the object's edges due to varying distances from the lens, leading to measurement errors. Telecentric lenses, however, employ a unique design where the principal rays enter the lens parallel to the optical axis. This eliminates perspective distortion, ensuring consistent edge imaging regardless of the object's distance from the lens. Consequently, they enable high-precision dimensional measurement of thick objects.

2. Inspection of Parts with Multiple Elevated Surfaces

Automated production lines often require inspecting parts positioned at varying heights, such as multi-layer circuit boards or stacked mechanical components. Conventional industrial lenses produce blurred or distorted images of parts at different heights due to focal length variations, compromising detection accuracy. Telecentric lenses provide constant magnification unaffected by changes in subject-to-lens distance, ensuring clear imaging of parts at all heights. This significantly enhances inspection efficiency and precision.

3. Cylinder Diameter Measurement

Measuring the diameter of cylindrical parts presents another major challenge in industrial inspection. Conventional industrial lenses distort edge imaging when capturing cylinders due to their curved surfaces, leading to inaccurate diameter measurements. Telecentric lenses, with their parallel optical path design, effectively minimize this geometric distortion. This enables more precise and reliable diameter measurement for cylinders, which is particularly crucial for manufacturing precision parts requiring strict dimensional control.

4. Gap Inspection in Precision Assembly

During precision assembly, gap control between components directly impacts product performance and reliability. Conventional industrial lenses struggle with depth-of-field limitations and light diffraction when imaging minute gaps, leading to measurement inaccuracies. Telecentric lenses, characterized by their large depth-of-field and low distortion, accurately capture subtle gap variations while maintaining high resolution, providing reliable data support for precision assembly.

5. High-Precision 2D Planar Measurement

For applications requiring high-precision 2D planar measurement—such as semiconductor chip inspection and dimensional verification of precision machined parts—standard industrial lenses may introduce measurement deviations due to inherent aberrations and chromatic aberrations. Telecentric lenses significantly reduce these errors through optimized optical design, delivering exceptional measurement accuracy and repeatability to meet the stringent demands of high-precision 2D planar measurement.

Telecentric lenses demonstrate unparalleled performance in scenarios such as measuring the dimensions of thick objects, inspecting parts with multiple planar heights, measuring cylindrical diameters, detecting gaps in precision assemblies, and performing high-accuracy two-dimensional planar measurements. Their unique advantages—eliminating perspective distortion, providing constant magnification, minimizing geometric distortion, offering a large depth of field, and exhibiting low aberration—make them indispensable tools for these high-precision inspection tasks, far surpassing the capabilities of conventional industrial lenses.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com