Applications of Motorized ZOOM LENS in Medical Microscopy and Scientific Observation

Traditionally, motorized ZOOM LENS have been predominantly used in industrial inspection applications, where they enable precise and efficient quality control on production lines. However, with continuous technological advancements, their application boundaries are being continually expanded. In cutting-edge fields such as medical microscopy and scientific observation, motorized ZOOM LENS are leveraging their unique advantages to drive the deep integration of automation and digitalization, bringing unprecedented transformations to life science exploration and materials analysis research.

I. Life Sciences: The “Intelligent Key” to Unlocking the Mysteries of Microscopic Life

In the vast realm of life sciences, the observation and study of microscopic samples such as cells and tissues are pivotal to unraveling the mysteries of life and conquering disease challenges. With their multi-scale observation capabilities, motorized ZOOM LENS have become indispensable “intelligent keys” in this field.

1. Multi-scale Automated Sample Scanning: Comprehensive Insights into Life's Details

Biological specimens possess complex and diverse structures, ranging from macroscopic tissues and organs to microscopic cells and subcellular structures, with distinct biological information concealed at different scales. Motorized ZOOM LENS enables continuous automatic magnification from low to high levels, allowing comprehensive and systematic scanning of samples without manual intervention. For instance, during pathological slide observation, the lens can first rapidly locate the lesion area at low magnification before swiftly switching to high magnification for detailed examination of cellular morphology and arrangement patterns. This provides rich, comprehensive information essential for accurate disease diagnosis.

2. Digital Slicing Technology: A “Virtual Sample Library” That Breaks Through Spatial and Temporal Constraints

Traditional microscopic observation is constrained by the physical space of the slide and the field of view of the microscope, making it difficult to achieve complete, continuous observation of large-sized samples. Motorized ZOOM LENS combined with advanced image stitching technology enables the creation of digital slides. By automatically scanning different regions of the sample and seamlessly stitching together the acquired high-resolution images, a complete, digital virtual specimen is generated. This technology not only overcomes temporal and spatial constraints, allowing researchers to review and analyze samples anytime, anywhere, but also facilitates remote collaboration and data sharing, significantly enhancing research efficiency.

3. High-Precision Measurement: Quantifying Vital Signs to Support Accurate Research

In life science research, precise measurement of characteristics such as cell size, morphological parameters, and tissue thickness forms the foundation of quantitative analysis. Motorized ZOOM LENS, equipped with high-precision positioning systems and advanced image processing algorithms, enables highly accurate measurements of sample characteristics. For instance, in neuroscience research measuring synapse lengths or in cell biology determining cell diameters, motorized ZOOM LENS provides precise and reliable data support, offering robust assurance for the precise study of biological phenomena.

II. Materials Analysis Field: The “Precision Probe” for Dissecting Material Structures

The advancement of materials science hinges on in-depth analysis of material microstructures. With their exceptional performance, motorized ZOOM LENS serve as “precision probes” for dissecting material structures, providing crucial insights for material design, preparation, and performance optimization.

1. Multiscale Structural Characterization: A Comprehensive Analysis from Macro to Micro

The properties of materials are closely related to their microstructure. Motorized ZOOM LENS enable comprehensive characterization of materials, from macroscopic morphology to microscopic structures such as grains and defects. In metal research, the lens can first examine the overall surface morphology at low magnification to detect macroscopic defects like cracks or scratches. It then switches to high magnification for detailed analysis of microstructural features—including grain size, orientation, and phase distribution—providing critical insights for evaluating mechanical properties and optimizing heat treatment processes.

2. Automatic Scanning and Image Analysis: Enhancing Analytical Efficiency and Standardization

Traditional material analysis often requires researchers to manually operate microscopes, observing and recording each region individually. This approach is not only inefficient but also susceptible to human error, resulting in poor standardization and reproducibility of analytical results. Motorized ZOOM LENS integrated with automated control software enables automatic scanning and image acquisition of material samples. Researchers need only set scanning parameters, after which the lens autonomously completes observation of the entire sample along a preset path, transmitting acquired image data to a computer for subsequent analysis. This process significantly enhances analytical efficiency while ensuring standardized and repeatable results.

3. High-Precision 3D Reconstruction: Three-Dimensional Visualization of Material Internal Structures

For materials with complex internal structures, such as composites and porous materials, two-dimensional microscopic images often struggle to comprehensively and accurately reflect their internal features. Combining motorized ZOOM LENS with 3D reconstruction technology enables high-precision three-dimensional reconstruction of material internal structures. By capturing a series of images at different focal planes and processing and fusing these images using advanced algorithms, a realistic 3D model is generated. Researchers can examine the material's internal structure from multiple angles, gaining deeper insights into its composition and architecture. This provides more intuitive and accurate guidance for material design and performance optimization.

III. Integration of Automation and Digitalization: Pioneering New Frontiers in Scientific Research

The application of motorized ZOOM LENS in medical microscopy and scientific observation not only enables automated scanning, digital sectioning, and high-precision measurement, but more importantly, drives the deep integration of automation and digitalization. By closely integrating with computer technology, image processing technology, artificial intelligence technology, and more, motorized ZOOM LENS establish an intelligent, digital scientific observation platform.

On this platform, data acquisition, processing, analysis, and storage are fully automated and digitized, significantly reducing manual intervention and enhancing research efficiency. Simultaneously, digital data facilitates long-term preservation and sharing, streamlining scientific collaboration and academic exchange. Furthermore, leveraging artificial intelligence algorithms to analyze and mine vast observational datasets enables the discovery of underlying patterns and trends within the data, providing fresh perspectives and directions for scientific innovation.

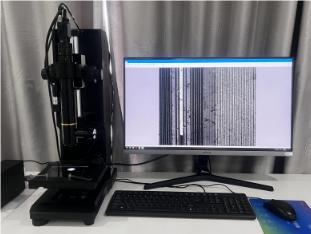

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com