In the fields of electronics manufacturing and semiconductor packaging, solder balls serve as critical interconnect materials, with their dimensional accuracy directly impacting device electrical performance and reliability. As electronic products evolve toward miniaturization and higher density, solder ball diameters have generally shrunk to 0.6mm or even smaller. However, measuring the dimensions of such ultra-micro components has long faced two major challenges: First, traditional measurement tools (such as calipers and projectors) struggle to achieve efficient inspection due to insufficient resolution or complex operation. Second, manual individual measurement is inefficient and prone to causing deformation of solder balls through contact-based handling, further compromising measurement accuracy.

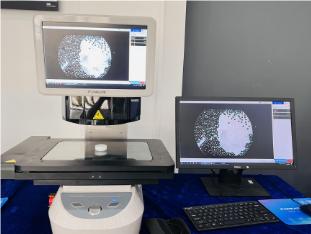

Against this backdrop, the POMEAS image measuring instrument has emerged as an innovative solution to the challenge of measuring 0.6mm solder balls, leveraging its non-contact, batch measurement capabilities and sub-micron precision.

I. Limitations of Traditional Measurement Methods

-

Insufficient Accuracy: Conventional measuring equipment (such as micrometers and optical projectors) typically has a resolution of 0.01mm, making it difficult to meet the tolerance requirement of ±0.005mm for 0.6mm solder balls. Additionally, contact-based measurement may cause deformation of solder balls due to uneven force application, introducing systematic errors.

-

Inefficient Process: Manual individual measurement requires repeated repositioning and focusing, taking approximately 30 seconds per solder ball. Inspecting thousands of solder balls consumes hours, while fatigue-induced human error becomes a significant risk.

-

Challenging Data Management: Traditional methods rely on manual data recording, hindering batch statistical analysis and trend tracking. This approach fails to meet modern production demands for quality traceability and process control.

II. Technical Breakthroughs in the POMEAS Image Measuring Instrument

The POMEAS Image Measuring Instrument integrates high-resolution industrial lenses, intelligent algorithms, and automated control technology to achieve non-contact, batch-processing, high-precision measurement of 0.6mm solder balls. Its core advantages are as follows:

-

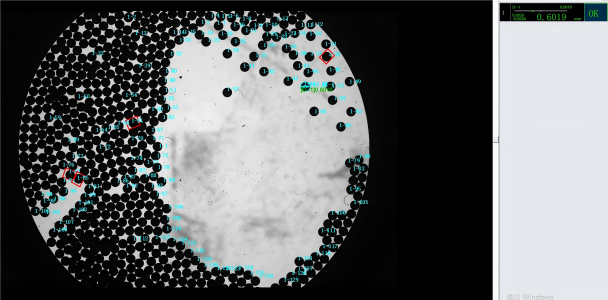

Sub-micron precision (0.001mm): Utilizing a combination of industrial cameras exceeding 20 million pixels and telecentric lenses, paired with sub-pixel edge extraction algorithms, enables precise identification of solder ball contours. Even when encountering reflective surfaces or slightly deformed solder balls, measurement repeatability remains ≤0.002mm.

-

100x Faster Batch Measurement Efficiency: Utilizing a multi-station stage and auto-focus functionality, it simultaneously measures 100-1000 solder balls per run without manual intervention. Batch measurement time is reduced to under 30 seconds, achieving over 100 times the efficiency of traditional methods.

-

Intelligent Data Analysis and Report Generation: The built-in Statistical Process Control (SPC) module calculates key metrics like CPK values and standard deviation in real time. It automatically generates ISO-compliant inspection reports and supports seamless integration with MES systems, enabling closed-loop quality data management.

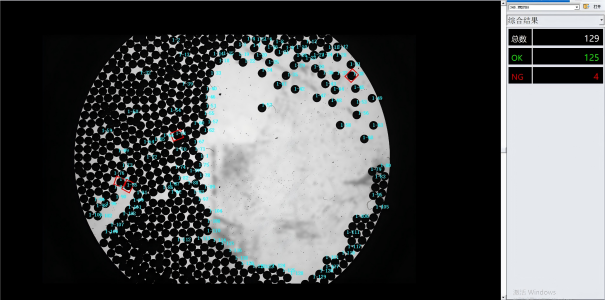

III. Test Results

Achieve measurement of over 100 items at once

Measurement accuracy can reach 0.0001 mm

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com