In the fields of industrial automation and machine vision, the selection of FA lenses directly impacts the precision and efficiency of four core tasks: recognition, measurement, positioning, and surface inspection. This article presents a lens selection strategy based on task characteristics, starting from application scenarios, to help engineers quickly match the optimal solution.

I. Visual Identity

Distinguishing objects from backgrounds through image features requires high contrast and sharp edges.

Selection Strategy:

-

Low Distortion Design: Select lenses with distortion rates <0.1% to prevent feature loss due to image edge distortion.

-

High Resolution: Prioritize megapixel-level lenses (e.g., 1.1" large-pixel sensors) to ensure discernibility of minute features.

-

Large Aperture & High Light Transmission: Lenses with F-value ≤1.8 increase light intake, enhancing contrast when paired with high-brightness light sources (e.g., ring LEDs).

-

Working Distance Adaptation: Select appropriate focal lengths based on target dimensions to prevent blurring due to insufficient depth of field.

-

Typical Applications: Barcode/QR code recognition, character OCR, part sorting.

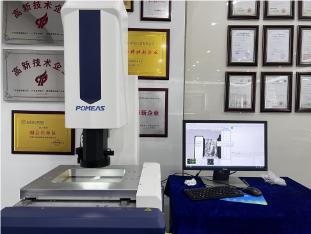

II. Visual Measurement

Eliminate perspective errors to achieve absolute precision measurement of dimensions and geometric parameters.

Selection Strategy:

-

Dual telecentric or object-side telecentric lenses: Ensure parallelism between object-side and image-side principal rays, eliminating measurement errors caused by variations in working distance.

-

Low magnification and long depth of field: Select lenses with 0.1×-0.5× magnification paired with coaxial illumination to achieve micrometer-level precision.

-

High MTF values: Central MTF ≥ 0.5 (50 lp/mm), peripheral MTF ≥ 0.3, guaranteeing full-field clarity.

-

Temperature stability: Utilize materials with low thermal expansion coefficients to minimize environmental temperature effects on optical performance.

-

Typical applications: Precision component dimensional measurement, thread parameter inspection, PCB solder joint height analysis.

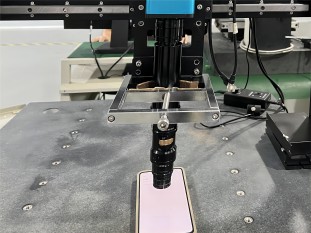

III. Visual Positioning

Rapidly lock onto target locations while balancing precision and real-time performance.

Selection Strategy:

- Low Distortion and High Speed: Select lenses with distortion rates <0.3% paired with CMOS global shutter cameras to minimize motion blur.

- Wide Angle and Short Focal Length: 12mm-25mm focal length lenses expand the field of view, increasing coverage per frame.

- Infrared Compatibility: Optional 850nm/940nm infrared band lenses for nighttime or low-light positioning.

- Vibration-Resistant Design: Metal housing and anti-loosening screws withstand industrial vibration environments.

- Typical Applications: Robot gripper positioning, AGV navigation, packaging box alignment inspection.

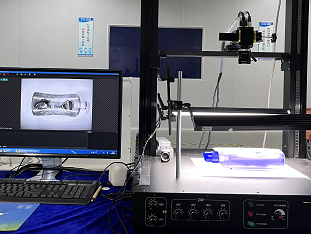

IV. Surface Visual Inspection

Detecting surface defects such as scratches, stains, and cracks requires high sensitivity and specificity.

Selection Strategy:

- Macro or ZOOM LENS: The 0.5×-5× ZOOM LENS allows flexible adjustment of magnification levels to accommodate defects of varying sizes.

- High Numerical Aperture (NA): Lenses with NA ≥ 0.3 enhance light collection capability, improving detection of faint signals.

- Polarization Compatibility: Optional polarizing filters eliminate surface reflection interference. Applications include smartphone glass scratch inspection, semiconductor wafer surface contamination analysis, and pharmaceutical packaging seal integrity testing.

V. Comprehensive Selection Process

- Prioritize tasks: Identify → Measure → Locate → Inspect, ranked by precision requirements.

- Match optical parameters: Calculate required focal length and magnification based on working distance, field of view, and resolution.

- Environmental adaptability: Consider the impact of temperature, vibration, and lighting conditions on lens performance.

- Cost and compatibility: Select models compatible with cameras, light sources, and software within budget constraints.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com