I. Core Inspection Requirements for Micro Gears (Diameter < 1mm)

Micro gears with diameters less than 1 mm are widely used in micro motors, precision instruments, medical devices, and other fields. Their inspection must meet three core requirements:

- Ultra-high precision fitting: Due to their minute dimensions, geometric tolerances typically require ±0.001 to ±0.005 mm. Inspection equipment must possess nanometer-level measurement resolution to prevent assembly jamming or transmission failure caused by insufficient precision.

- Non-contact Measurement: Microgear tooth surfaces are fragile and prone to deformation. Traditional contact measurement methods (e.g., probe-based) may cause surface scratches or gear distortion. Non-contact measurement must be employed to preserve workpiece integrity.

- Full Parameter Coverage and Efficiency: Multi-dimensional parameter inspection must be completed rapidly, balancing comprehensive testing with production efficiency to meet quality control demands in batch manufacturing scenarios.

II. Core Content of Full-Parameter Inspection for Micro Gears

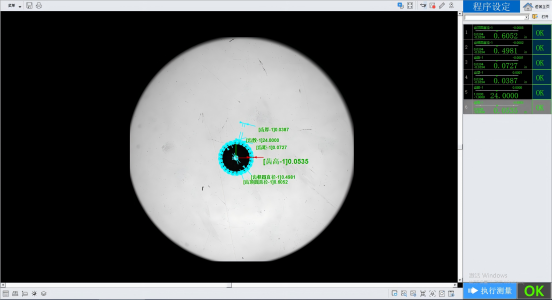

For micro gears with diameters <1mm, the image measuring instrument must achieve precise analysis of the following key parameters, covering core performance indicators of gear transmission:

- Basic geometric parameters: Including tip circle diameter (da), root circle diameter (df), pitch circle diameter (d), and tooth width (b). Precise capture of gear profile boundaries is required to eliminate the impact of edge blurring on dimensional measurement.

- Tooth Profile and Pitch Parameters: Tooth profile error (ffα), cumulative pitch error (Fp), and individual pitch deviation (fpt) directly affect gear meshing smoothness. These require clear identification of tooth profile curves and pitch intervals through magnification imaging technology.

- Tooth thickness and pitch line parameters: Fixed chord tooth thickness (sxn), pitch line length (Wk). These determine the rationality of gear meshing clearance, requiring enhanced measurement accuracy through image stitching and data fitting techniques.

- Runout Errors: Radial runout (Fr) and end face runout (Ft) reflect the coaxiality and perpendicularity of the gear mounting reference. Error detection relies on high-precision workbenches and image positioning algorithms.

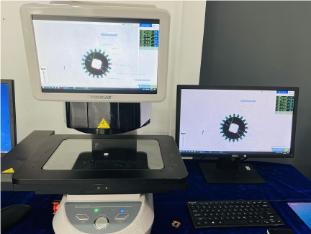

III. Advantages of the POMEAS Image Measuring Instrument for Microgear Measurement

1. Ultra-high resolution imaging breaks through micro-dimension recognition bottlenecks: Equipped with high-magnification optical lenses and CMOS industrial cameras, achieving pixel resolution down to 0.1μm. Combined with sub-pixel subdivision algorithms, it clearly restores profile details, minute chamfers, and tooth surface textures of gears with diameters <1mm, eliminating measurement errors caused by blurred imaging.

2. Non-contact measurement for full protection of fragile components: Data acquisition via optical imaging eliminates direct contact with gear tooth surfaces, completely preventing surface scratches and gear deformation caused by contact measurement. This approach is particularly suited for inspecting thin-walled, high-precision micro-gears.

3. Intelligent algorithm-driven full-parameter auto-analysis: Built-in specialized gear measurement modules automatically identify key features like tooth tips, roots, and pitch circles. One-click calculation of all parameters—including tip circle diameter, pitch error, and runout error—eliminates manual point-finding, boosting measurement efficiency by 3–5 times while preventing human operational errors.

4. High-precision mechanical structure ensures measurement stability: Utilizes a marble worktable and high-precision linear guides, achieving motion accuracy of ±0.002mm/m. Effectively resists environmental vibrations and temperature variations, guaranteeing repeatability accuracy ≤0.001mm for gears <1mm in diameter, meeting mass production quality control standards;

5. Data visualization and traceability for quality control: Supports automatic measurement data storage and report generation, with exportable Excel and PDF files. Clearly displays parameter deviation values and pass/fail results, facilitating quality traceability and production process optimization.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com