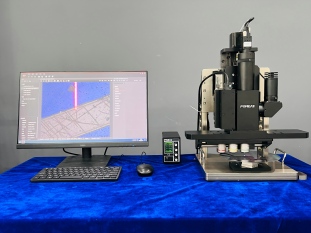

1. Highly automated, reducing reliance on manual labor

01. Intelligent Focus Control: Utilizing laser ranging and closed-loop feedback mechanisms, the system dynamically adjusts the distance between the objective lens and the wafer surface in real time, achieving stable focusing without manual intervention.

02. Typical Comparison: Traditional microscopes require operators to repeatedly adjust the Z-axis knob, a time-consuming process prone to errors due to fatigue. In contrast, the laser system performs the entire process autonomously, making it particularly suitable for batch inspection scenarios.

03. Extended Value: Supports integration with MES/ERP systems to enable fully automated inspection across production lines, significantly reducing labor costs.

2. Ultra-high-speed inspection, breaking through production capacity bottlenecks

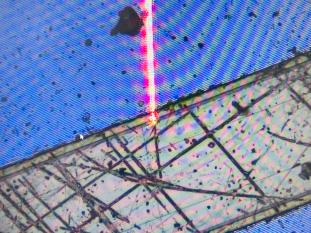

01. Millisecond Response Speed: Laser-triggered autofocus locks onto the target plane within milliseconds. Combined with high-speed stage movement, single-wafer inspection time is reduced to one-third to one-fifth of traditional equipment.

02. Continuous Operation Capability: An automated process with no mechanical pauses, ideal for high-throughput wafer production demands.

03. Time Savings: For a single 12-inch wafer, conventional inspection takes 5 minutes, while this system completes it within 90 seconds, directly boosting overall equipment effectiveness.

3. Sub-micron AF Precision Ensures Detection Reliability

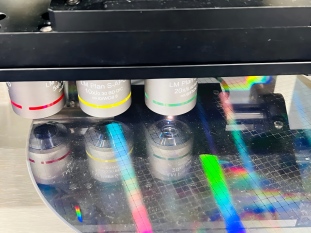

01. Nanometer-level repeatability: Piezoelectric ceramic motors (PZT) calibrated with helium-neon laser interferometers achieve vertical positioning accuracy of ±5nm, far surpassing the micrometer-level errors of manual adjustments.

02. Core technology support: Confocal principle + AI image recognition algorithms precisely distinguish true topography from out-of-focus artifacts, preventing over-detection or missed defects.

03. Quantified Outcomes: Detection rates for sub-14nm advanced process features—such as photoresist residues and particulate contamination—exceed traditional brightfield illumination by over 30%.

4. Enhanced Full-Process Quality Control

01. Eliminate Subjective Judgment Variations: Standardized optical parameters (wavelength/numerical aperture/illumination intensity) eliminate judgment errors caused by operator experience.

02. Big Data Traceability System: Each image frame includes metadata such as focal length compensation values and coordinate positions, facilitating defect traceability and process review.

03. Enhanced foolproof mechanism: The system automatically pauses and triggers an alarm upon detecting abnormally tilted wafers, preventing collision accidents and safeguarding expensive samples.

5. Multi-dimensional Application Scalability

01. Cross-Process Adaptability: From measuring film thickness on polished flat surfaces to inspecting steep aspect ratio trenches after etching, the system automatically adjusts depth-of-field range through algorithmic adaptation.

02. Special Material Compatibility: For samples with highly variable reflectivity, such as semiconductors and transparent substrates, optional multi-wavelength light source modules are available.

03. Intelligent Iteration Potential: The accumulated inspection database can be used to train deep learning models, continuously optimizing threshold segmentation and classification accuracy.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com