Fundamental Principles and Structural Characteristics of Industrial Line-Scan Cameras

Line-scan lenses are specialized optical systems designed specifically for line-scan cameras, operating on a fundamentally different principle than conventional area-scan lenses. While traditional area-scan lenses capture the entire field of view in a single exposure using a two-dimensional pixel array, line-scan lenses employ a linear scanning method. They continuously acquire image data from the target object using a single row of photosensitive elements, then synthesize the complete image through motion. This unique operating mechanism endows line-scan lenses with several distinctive structural characteristics.

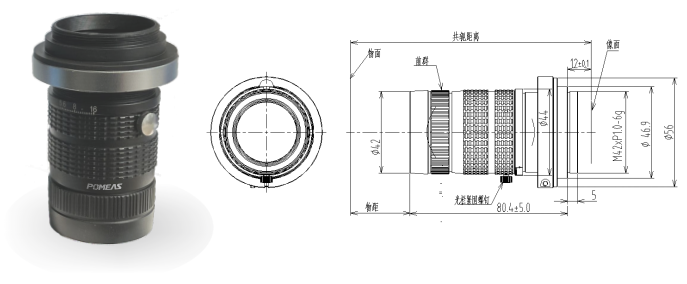

Large image circle design stands as one of the most distinctive features of line scan lenses. Professional models typically incorporate large sensor formats ranging from φ32mm to φ82mm. This design effectively covers the long edge dimensions of line scan sensors, ensuring sufficient imaging coverage during scanning. Compared to standard lenses, the optical systems of line scan lenses undergo specialized optimization to maintain consistent relative illumination and resolution across the entire image circle, thereby preventing image quality degradation at the edges.

Regarding optical parameters, line-scan lenses typically feature narrower field-of-view angles. This narrow perspective, combined with long focal lengths (commonly 70mm, 80mm, 90mm, 100mm, etc.), enables higher magnification at working distances. Notably, even at their maximum aperture of F2.8, modern high-performance line-scan lenses maintain sufficient resolution to meet the demands of 100-megapixel sensors like the GFX100s across 70% of the central area. This ability to deliver sharpness wide open is particularly crucial in industrial inspection applications.

Core Performance Advantages of Industrial Line-Scan Cameras

High-speed imaging capability is the primary advantage that distinguishes line scan lenses from conventional lenses. Utilizing a single-line scanning mechanism, line scan lenses paired with line scan cameras achieve microsecond exposure times and scanning frequencies reaching tens of kHz. This high-speed performance enables them to clearly capture objects moving at high speeds on conveyor belts. For instance, in lithium battery electrode sheet inspection, they deliver stable imaging at production line speeds exceeding 100 meters per minute, fully meeting modern industry's pursuit of ultimate production efficiency.

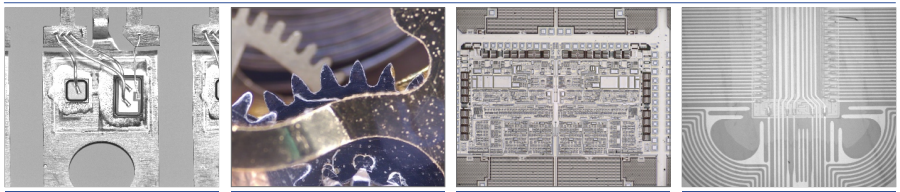

In terms of resolution performance, professional-grade line scan lenses demonstrate exceptional capabilities. Represented by the VPLL series, 4K, 8K, and even 16K line scan lenses employ high-resolution optical system designs, achieving resolution capabilities exceeding 200 lp/mm. This enables clear identification of micron-level defects. This exceptional detail resolution makes them outstanding for applications like printed circuit board inspection and precision component measurement, where even 0.01mm scratches or foreign objects are detected without fail.

Infinite-length imaging capability represents another major technical highlight of line scan lenses. Based on the “scan-synthesis” principle, line scan systems can theoretically perform seamless inspection of objects of any length, making them particularly suitable for in-line inspection of roll materials. In surface defect detection of continuous materials such as metal foils (e.g., lithium battery copper foil/aluminum foil), photovoltaic backsheets, and non-woven fabrics, line scan lens systems demonstrate irreplaceable advantages, achieving large-area coverage capabilities unattainable by traditional area scan systems.

Typical Application Scenarios for Industrial Line-Scan Cameras

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com