Why does the choice of industrial lenses determine the upper limit of a visual system?

When building machine vision systems, a common misconception is that users are often willing to invest heavily in top-tier industrial cameras with the highest resolution, yet hesitate when selecting lenses—sometimes even pairing them with ordinary lenses. This is akin to equipping a priceless high-end DSLR camera with a cheap “dog-head” lens.”——No matter how powerful the camera sensor may be, it cannot compensate for the performance loss caused by the front-end optical components.

Blurred image edges, loss of fine details, measurement results fluctuating unpredictably with object position... When your vision system exhibits these issues, the root cause likely lies with its “eyes”—the industrial lenses.

Decoding the Core “Optical Quality” of Industrial Lenses

To select a pair of qualified “eagle eyes,” we need to understand several core optical metrics:

1. Resolution: This does not refer to the camera's pixel count, but rather the lens's inherent ability to reproduce fine details of objects. A high-resolution lens complements and maximizes the potential of a high-pixel-count camera, ensuring every pixel in the image contains true, sharp information. Conversely, a low-resolution lens becomes a bottleneck in the system, resulting in blurry images.

2. Distortion: This can be understood as the optical equivalent of a “funhouse mirror” effect. It causes deformation in the image of objects, bending straight lines and distorting circles into ellipses. For high-precision dimensional measurement, distortion is a critical source of error. Therefore, professional industrial inspection lenses, especially telecentric lenses, employ specialized optical designs to minimize distortion to extremely low levels, ensuring measurement accuracy.

3. Depth of Field: This refers to the range within an object's spatial plane where images remain sharp. When inspecting objects at varying heights, sufficient depth of field ensures the entire target area remains clearly visible. Insufficient depth of field may necessitate solutions such as stacking images from different focal planes or employing systems with autofocus capabilities.

How to choose the best “eyes” for your application?

Scenario 1: High-Precision Dimensional Measurement

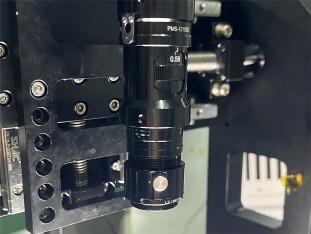

Opt for a telecentric lens. This is the only choice when precision is required. Telecentric lenses utilize a unique parallel optical path design that effectively eliminates perspective errors caused by changes in object position or surface irregularities. This ensures that measured dimensions match actual dimensions regardless of the object's position within the field of view—a capability ordinary lenses cannot achieve.

Scenario 2: Surface Defect Detection

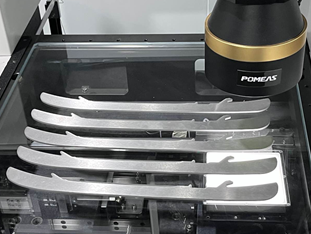

Select: High-resolution, low-distortion prime lenses. The core requirement for such applications is the ability to “detect” defects. The lens must possess extremely high resolution to capture minute scratches and blemishes, while maintaining minimal distortion to ensure the true form of defects is accurately reproduced, thereby preventing misjudgment.

Scenario 3: Observation at a Specific Working Distance

Select a macro lens or a lens with a specific focal length. When working in confined spaces or photographing extremely small objects, a macro lens delivers sharp images and high magnification at extremely close distances.

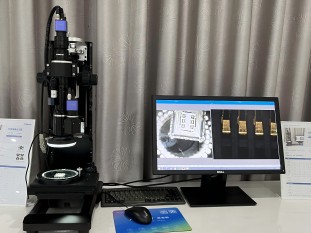

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com