What parameters should be considered when selecting an image measuring instrument?

In industrial quality inspection, many struggle when selecting image measurement instruments—either facing insufficient accuracy that leads to product misjudgment, or excessive parameters that result in wasted costs. This article guides you through optimizing core parameters and refining them for specific scenarios in just one minute. It helps you quickly pinpoint the right measurement solution tailored to your needs, eliminating the need to repeatedly agonize over the “parameter fog.”

I. Core Parameters to Consider When Selecting Models: How Image3 Precisely Meets Your Needs

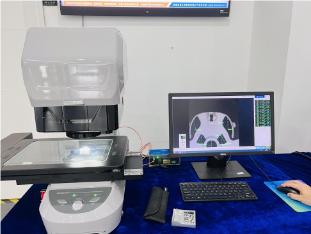

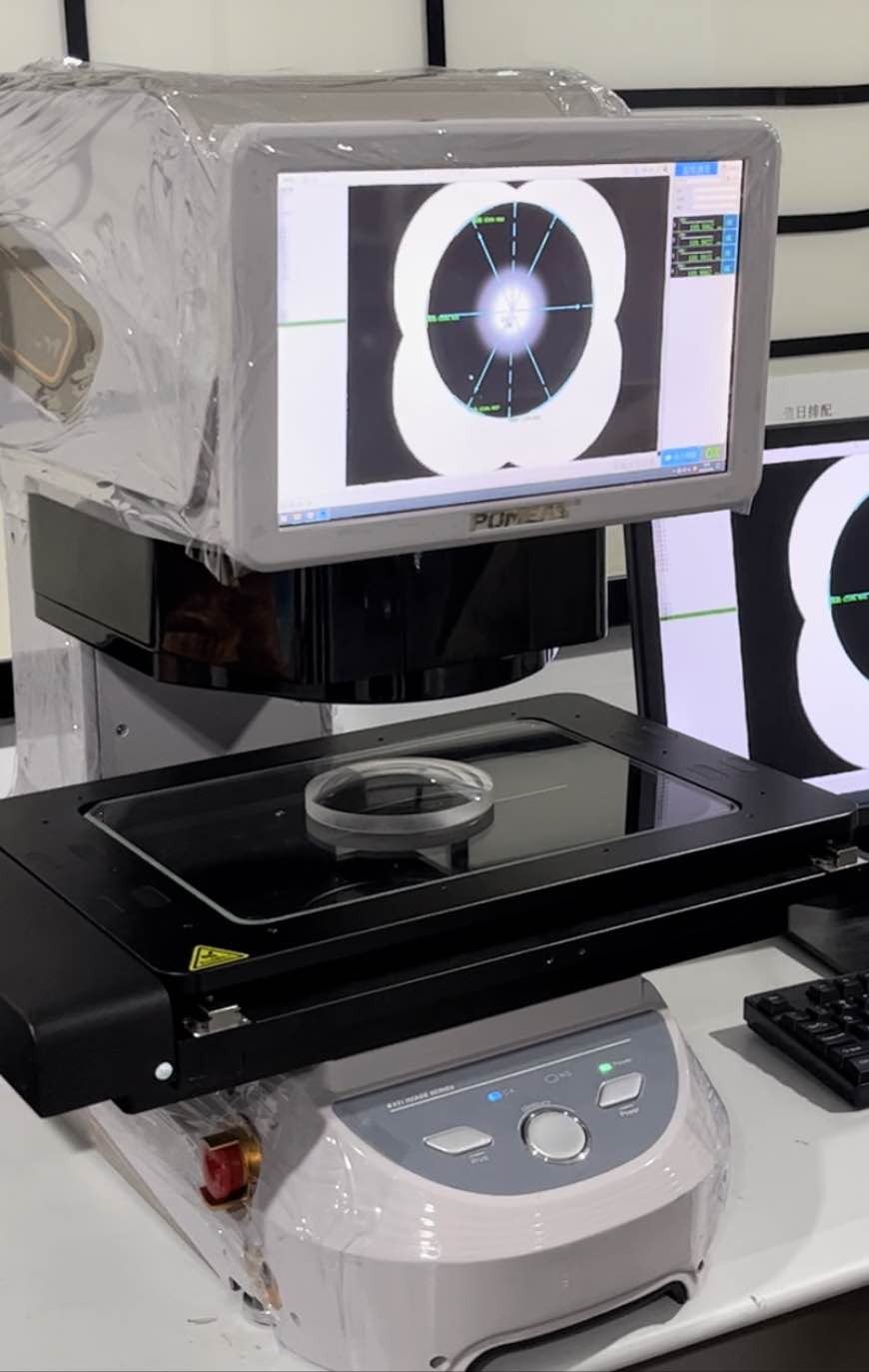

Understanding the core parameters of a measuring instrument is the first step in selecting the right equipment. The optimized design of the POMEAS Image3 in key parameters fully meets the measurement requirements of different workpieces, avoiding issues of wasted or insufficient accuracy.

1. Measurement Accuracy: As a core selection criterion, it must prioritize matching the permissible error range of workpieces. The POMEAS Image3 delivers high display accuracy and repeatability, capable of handling high-precision measurements down to 0.001mm for precision hardware components while reliably meeting standard inspection requirements for conventional workpieces. This effectively mitigates product quality risks caused by accuracy deviations.

2. Resolution: Resolution determines the device's ability to detect minute dimensional changes. Image3 incorporates a high-pixel industrial camera, with resolution precisely matching measurement accuracy requirements. For instance, it achieves ≥0.5μm resolution for 0.001mm precision needs, ensuring clear capture of minute features.

3. Field of View: Selection should align with the workpiece's maximum measurement dimensions. Image3 supports multiple field-of-view specifications, covering measurement needs from small precision components to medium-sized workpieces. For oversized workpieces, its automatic stitching function eliminates errors caused by manual movement, enhancing measurement efficiency for large components.

4. Magnification: Magnification must balance measurement accuracy and field of view. Image3 features interchangeable lenses with multiple magnification options. High-magnification modes are ideal for measuring minute features like 0.1mm-level apertures and fine lines, while low-magnification modes enable rapid overall inspection of large 100mm-level workpieces without frequent equipment switching.

5. Light Source Type: Light sources directly impact image clarity. Image3 offers multiple light source options including coaxial light, ring light, and diffuse light. Coaxial light clearly reveals contour edges during transparent lens measurements, while ring light or diffuse light enhances feature contrast for plastic and metal parts, ensuring measurement accuracy across diverse materials.

II. Typical Application Scenarios: Image3 Enables High-Precision Inspection

POMEAS Image3 not only boasts superior specifications but also demonstrates exceptional adaptability in real-world applications, particularly excelling in the following two high-frequency scenarios:

(1) Lens Profile Scanning Measurement: As high-precision transparent components, lenses demand exceptional accuracy in measuring contour edges. Image3 employs a high-resolution camera paired with a coaxial light source to precisely capture intricate details such as curved profiles and chamfers. This approach eliminates measurement errors caused by reflections or light transmission in transparent materials, providing reliable precision assurance for optical component manufacturing.

(2) Plastic Component Dimension Measurement: Plastic parts are prone to slight deformation due to temperature and pressure, demanding greater measurement stability. Image3 leverages its outstanding repeatability to average multiple measurements, minimizing deformation effects. Its flexible field-of-view and light source combinations enable rapid inspection of plastic part dimensions—including aperture, wall thickness, and spacing—meeting the efficient quality control demands of mass production.

POMEAS Image3 precisely matches measurement requirements across industries through optimized core parameters and scenario-based design. Would you like me to prepare a specialized selection plan for the electronics, optics, and plastics industries? This plan will incorporate specific workpiece characteristics, provide clear parameter recommendations, and outline inspection workflows for your direct reference.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com