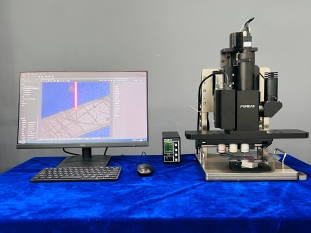

In the field of modern precision measurement, laser autofocus microscopy systems are revolutionizing inspection solutions across industries with their unique technological advantages. Integrating high precision, high efficiency, and intelligent capabilities, POMEAS laser autofocus microscopy systems have become powerful tools for industrial inspection and quality control.

Core Features of the Laser Autofocus Microscopy System

The POMEAS Laser Autofocus Microscope System features the following outstanding characteristics:

-

Nanometer-level focusing precision: Utilizes laser confocal principles to achieve micrometer- or even nanometer-level precision focusing

-

Non-contact measurement: Eliminates potential damage to sample surfaces caused by traditional contact-based measurement methods

-

Intelligent focusing algorithm: Automatically completes the focusing process rapidly, significantly enhancing inspection efficiency

-

Robust environmental adaptability: Maintains stable performance under complex conditions such as vibration and temperature fluctuations

-

Comprehensive Software Capabilities: Equipped with professional analysis software supporting 3D topography reconstruction and data analysis

Application Advantages in the Electronic Semiconductor Industry

In the field of electronic semiconductor manufacturing, this system demonstrates unique value:

-

Wafer Surface Inspection: Precise measurement of critical parameters such as wire line width and etch depth

-

Chip Packaging Inspection: Three-dimensional topography analysis of BGA solder balls, wire bonding, and other components

-

Material Surface Analysis: Accurate evaluation of quality metrics including material roughness and flatness

-

Automatic Defect Recognition: Rapid localization of minute surface defects such as scratches and pits

Technological Breakthroughs in Precision Manufacturing

For precision component manufacturing, the system delivers a perfect solution:

-

Complex Surface Measurement: Effortlessly handle dimensional inspection of intricate surfaces like gears and blades

-

Microstructure Analysis: Perform high-precision 3D measurement on micro-components and precision molds

-

Roughness Inspection: Achieve rapid, accurate assessment of nanoscale surface roughness

-

In-line Quality Control: Meet real-time inspection and quality monitoring demands on production lines

Innovative Applications in the Field of Scientific Research

In scientific research, the system demonstrates significant potential:

-

Materials Science Research: Enabling analysis and characterization of new material surface properties

-

Biomedical Research: Providing precise measurements for micro-medical devices, biological samples, and more

-

Micro-Nano Technology Research: Supporting cutting-edge research in microelectromechanical systems, nanomaterials, and related fields

Quality Assurance in the New Energy Industry

In the rapidly developing field of new energy, systems play a vital role:

-

Battery Electrode Inspection:Accurately measure critical parameters such as coating thickness and surface porosity.

-

Solar Cell Analysis:Perform precise inspection of silicon wafer surface texture and electrode dimensions

-

Fuel Cell Testing:Assist in evaluating the manufacturing quality of core components such as membrane electrodes.

The POMEAS Laser Autofocus Microscope System delivers reliable quality assurance to customers across diverse industries through its exceptional technical performance and extensive application expertise. Whether in R&D laboratories or production facilities, it provides stable and precise measurement solutions, empowering enterprises to enhance product quality and drive industrial advancement.

Precision Focus, Smart Manufacturing for Tomorrow—POMEAS Laser Auto-Focus Microscope System, Safeguarding Your Quality Control!

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com