In the quality control of metal wire materials (such as steel wire, copper wire, carbon fiber, etc.), precise diameter measurement is a critical step to ensure product consistency and process stability. Current mainstream technical solutions include flash gauges and online diameter measuring instruments, each with its own advantages and disadvantages, suitable for different application scenarios.

1. Principle of Operation of the Flash Tester

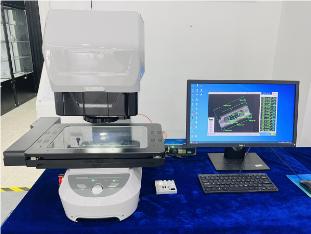

(1) Principle: Utilizes optical imaging and image processing technology to perform instantaneous contact/non-contact measurements on stationary samples. Typically requires manual sampling followed by placement on the testing platform to complete the inspection.

(2) Features: Rapidly obtains precise numerical values at specific points along individual filaments, suitable for laboratory environments or spot-check requirements. Some high-end models support multi-point measurement but still require segmented operation, achieving accuracy down to the micrometer level.

2. Online Diameter Measurement Instrument: Measurement Principle

(1) Principle: The laser emitter within the instrument generates a laser beam. Through optical scanning devices such as mirrors and rotating mirrors, the laser beam scans the surface of the measured object at a specific angle and speed.

(2) Features: Dynamically tracks materials in high-speed operation, enabling unattended monitoring throughout the entire process. Supports threshold alarm settings and automatic adjustment of process parameters via linked correction devices, achieving precision within ±0.5μm.

The optical imaging and image processing principles of flash measurement instruments make them particularly adept at capturing and analyzing comprehensive images of measured objects. They can measure the diameter of complex-shaped filaments and simultaneously obtain multiple dimensional data. However, they face limitations when measuring moving filaments due to their relatively time-consuming measurement process, which makes real-time tracking of filament dynamics challenging.

Among online diameter measurement instruments, laser scanning diameter gauges employ rapid scanning techniques to achieve real-time measurement of moving fine wires. Their high measurement speed makes them suitable for high-speed inspection on production lines, though their accuracy for measuring wires with extremely small diameters may be inferior to that of laser diffraction diameter gauges. Laser diffraction diameter measurement instruments offer exceptional measurement accuracy for small-diameter wires, reaching sub-micron levels. They are particularly suitable for scenarios demanding stringent precision, such as ultra-fine metal wire and semiconductor wafer diameter inspection. However, they impose strict requirements on the measurement environment and have a relatively narrow measurement range, typically applicable for small-diameter measurements between 5 and 500μm.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com