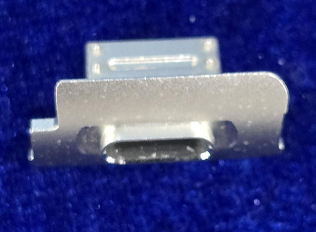

Image Dimension Measuring Instrument Application: Type-C Interface Dimension Measurement

Background of Type-C Interface Testing

With the rapid advancement of technology, the way electronic devices connect is undergoing unprecedented transformation. Among these, the USB Type-C interface has swiftly become the mainstream interface standard for modern electronic devices, thanks to its exceptional data transfer speeds, robust power delivery capabilities, and broad device compatibility. From smartphones to laptops, and across various peripherals and accessories, the Type-C interface is ubiquitous.

However, this widespread adoption also presents stringent quality control challenges. To ensure that each Type-C port operates reliably and efficiently, precise measurement of its physical dimensions has become an indispensable step in the manufacturing process. Against this backdrop, the introduction of advanced image dimension measurement instruments—particularly professional equipment like the POMEAS IMAGE 3PRO—holds significant importance for safeguarding the production quality of Type-C ports.

Type-C Interface Testing Requirements

Faced with increasingly stringent quality requirements, the testing demands for Type-C interfaces have become more meticulous and comprehensive. Specifically, these requirements are primarily reflected in the following aspects:

1. High-precision measurement: Due to the intricate internal structure of Type-C connectors, even minor dimensional deviations can compromise functionality and reliability, necessitating micron-level measurement accuracy.

2. Multifunctionality: Beyond basic two-dimensional measurements like length and width, the system must also measure three-dimensional features such as the height, spacing, and shape of internal metal springs.

3. Efficient automation: Considering the mass-production testing demands on assembly lines, the inspection process must be rapid, accurate, and fully automated to minimize manual intervention and enhance production efficiency.

4. Strong adaptability: Flexible capability to handle testing tasks for various models and versions of Type-C interfaces, meeting diverse product requirements.

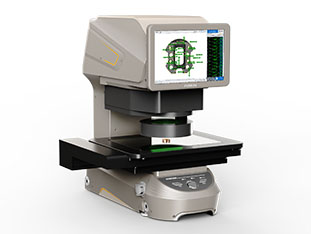

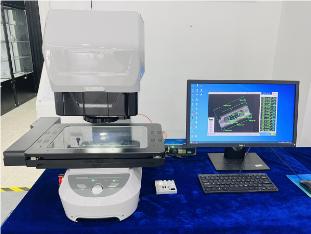

Inspection Solution - Image Size Measuring Instrument IMAGE 3 PRO

For the aforementioned Type-C interface inspection requirements, POMEAS's IMAGE 3PRO image dimension measuring instrument delivers a perfect solution. This device integrates a high-resolution camera, precision optical system, and advanced image processing software, specifically designed for high-precision measurement of micro-sized components.

1. High-Definition Imaging and Precise Positioning: Equipped with a high-definition camera, the IMAGE 3PRO captures every detail of Type-C connectors. Combined with a dedicated illumination system and focusing mechanism, it ensures crystal-clear, blur-free images, providing an accurate foundation for subsequent dimensional measurements. Through intelligent edge detection algorithms, it automatically identifies connector contours for rapid and precise positioning.

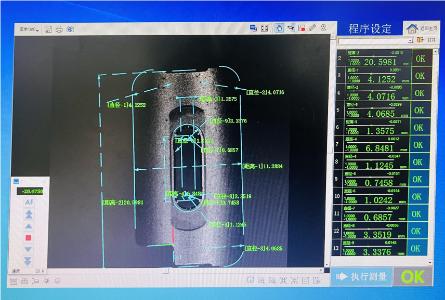

2. Comprehensive Dimensional Measurement Capabilities: Whether assessing overall interface dimensions or critical internal parameters like metal contact spacing and height, IMAGE 3PRO handles it effortlessly. Its integrated software platform supports multiple measurement tools—including straight-line distance, center-to-center distance, and angle measurement—to fulfill all Type-C interface dimensional inspection requirements.

3. Efficient Data Processing and Analysis: Upon completing measurements, IMAGE 3PRO instantly generates detailed reports containing dimensional data, deviation analysis, and pass/fail results. Additionally, its data export capability facilitates integration with production management systems for traceability and data management.

4. Flexible Configuration and Scalability: To address diverse customer requirements, IMAGE 3PRO offers extensive configuration options and customization services. Users can select appropriate lens magnifications, light source types, and even develop dedicated measurement programs tailored to specific inspection needs.

5. User-Friendly Interface: To enable operators to quickly master the system, IMAGE 3PRO features an intuitive and user-friendly interface design. Clear operational workflows and guidance prompts allow even non-specialists to learn device operation in a short time, significantly reducing training costs and lowering the learning curve.

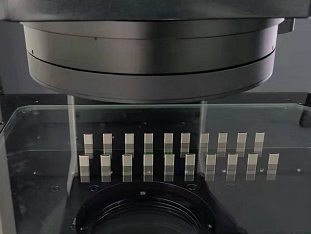

Type-C Port Test Results

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com