Application of High-Precision Image Measuring Instruments in Contour Measurement of Plastic Parts

I. Testing Background

During the production of plastic components, parts formed through injection molding often exhibit complex contour features such as height variations and curved surface transitions. Traditional planar dimensional measurement methods struggle to comprehensively capture the subtle deviations in these three-dimensional shapes, creating blind spots in quality control processes. Particularly in precision manufacturing, the demand for contour accuracy in plastic parts continues to rise, rendering simple two-dimensional measurement inadequate for meeting the stringent requirements of modern production.

II. Testing Protocol

To address the unique demands of plastic part contour measurement, POMEAS has introduced the high-precision MAX2 image measuring system. Combining advanced optical imaging technology with high-accuracy analysis algorithms, this device enables non-contact 2D and 3D measurement, effectively tackling inspection tasks involving complex contours such as curved surfaces and height differentials in plastic components.

Features of the Solution:

-

Non-contact measurement: Prevents deformation or damage to plastic parts caused by contact, ensuring the authenticity and accuracy of measurement data.

-

2D/3D Integration: Supports simultaneous measurement of two-dimensional dimensions and three-dimensional contours for comprehensive evaluation of plastic part geometry.

-

High Precision and High Efficiency: Equipped with a high-resolution camera and a precision motion control system, combined with intelligent image processing software, it rapidly completes data acquisition and analysis of complex contours.

-

Automated Operation: Customizable automation solutions tailored to user requirements enable batch testing, significantly boosting production efficiency.

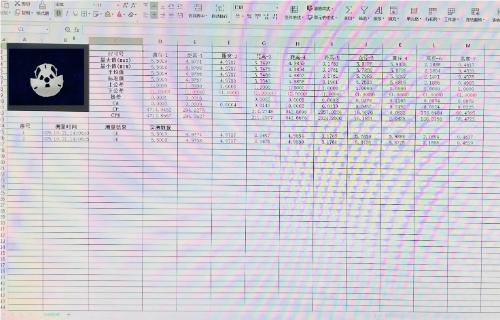

III. Test Results Presentation

The POMEAS MAX2 High-Precision Image Measuring Instrument delivers an efficient and reliable solution for plastic part contour measurement through its outstanding non-contact measurement capabilities and high-precision performance. Whether for sample analysis during the R&D phase or quality control in mass production, the MAX2 empowers enterprises to achieve refined, automated inspection management, driving continuous improvement in product quality.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION