Low-Distortion FA Lenses: Enabling Precision Visual Inspection Solutions for the 3C Industry

Low Distortion FA Lens

FA lenses are industrial lenses specifically designed for factory automation systems and visual inspection equipment. Featuring low distortion, high resolution, and high contrast, these lenses deliver clear, accurate images while minimizing detection errors caused by lens distortion. They serve as a core component for achieving precise visual inspection in the 3C industry.

Characteristics of Visual Inspection Requirements in the 3C Industry

3C products feature small component dimensions, high precision requirements, and rapid production speeds. This necessitates vision inspection systems capable of swiftly and accurately detecting product defects and dimensional deviations. For instance, scratches on mobile phone screens, deformation of chip pins, and dimensional accuracy of computer casings all require vision inspection to ensure quality. Low-distortion FA lenses meet the high-precision demands of the 3C industry for vision inspection, guaranteeing the reliability of inspection results.

Advantages of Low-Distortion FA Lenses

-

High-Precision Imaging: Low-distortion FA lenses effectively suppress distortion to ensure geometric accuracy in images. For instance, the POMEAS 10-megapixel 2/3-inch low-distortion industrial lens features distortion below 0.2%, delivering high-quality 10-megapixel imaging capable of clearly capturing intricate details in 3C products.

-

High resolution and contrast: These lenses offer high resolution and high contrast, enabling clear identification of minute features and defects in 3C products.

-

High Stability: Low-distortion FA lenses typically feature compact structural designs and high-quality materials, offering excellent shock resistance and environmental adaptability, enabling stable operation on 3C production lines.

Low Distortion FA Lenses in 3C Industry Applications

-

Mobile Screen Inspection: Low-distortion FA lenses can be used to detect scratches, bubbles, cracks, pixel defects, and other imperfections on mobile screens. Through high-precision imaging, they clearly display screen details to ensure screen quality.

-

Chip Inspection: During chip manufacturing, low-distortion FA lenses can be used to inspect chip dimensions, shape, pin placement, and deformation. Their high resolution and low distortion characteristics enable precise measurement of various chip parameters, ensuring chip performance and quality.

-

Precision Component Inspection: Many precision components in 3C products, such as camera modules, connectors, screws, and others, require high-precision visual inspection. Low-distortion FA lenses deliver clear images, enabling inspection systems to rapidly and accurately identify component defects and dimensional deviations.

Product recommendation

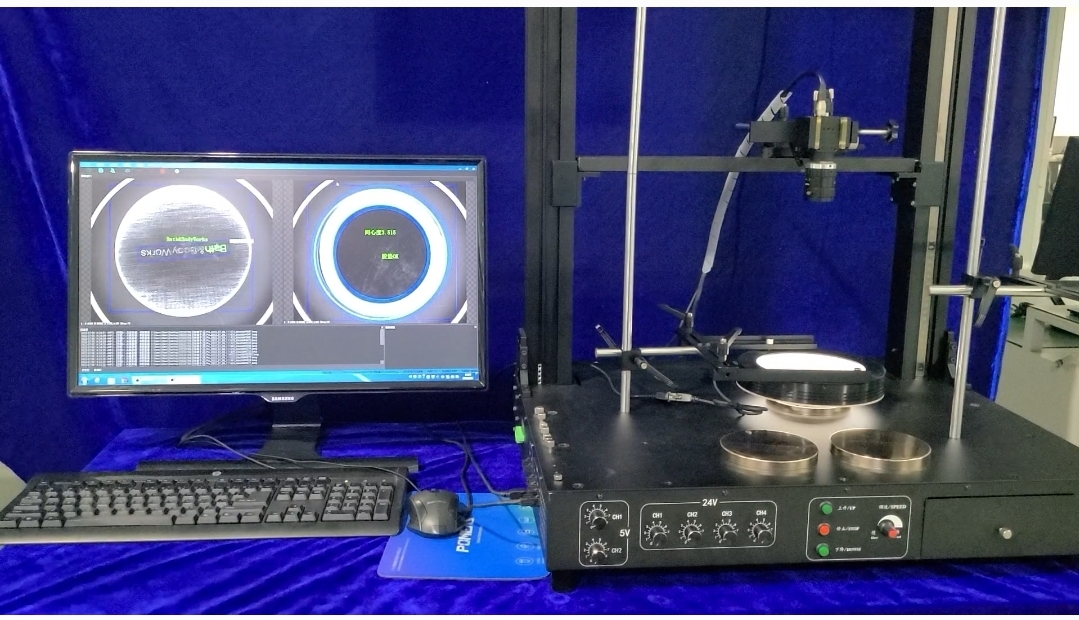

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com