Industrial Telephoto Lenses: The Eye of Precision Across Multiple Fields

In today's era of highly automated and intelligent industrial production, precise visual inspection and measurement have become indispensable critical components in numerous manufacturing processes. Industrial telecentric lenses, as high-end lenses featuring unique optical designs, demonstrate immense application value across multiple fields due to their outstanding image quality, extremely low distortion rates, and stable imaging performance.

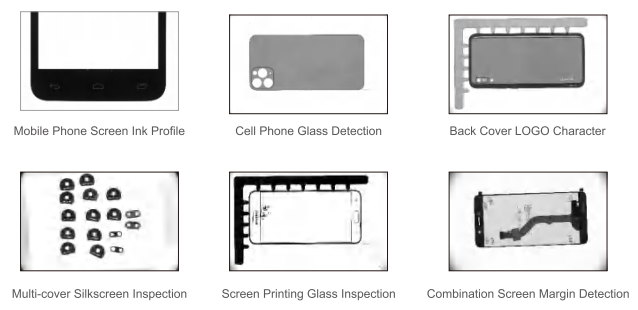

1. Electronics Manufacturing

① PCB Board Inspection: Provides uniform vertical illumination to eliminate shadows, accurately revealing intricate circuitry and precisely identifying defects such as short circuits and open circuits. After implementation at a certain electronics factory, defect rates decreased significantly.

② Electronic Component Visual Inspection: Features a large depth of field and high resolution to clearly display surface details of minute components, effectively detecting defects like scratches and stains while enhancing inspection efficiency and accuracy.

2. Semiconductor Industry

① Wafer Inspection: Flexibly switches between macro and micro modes. Parallel light beams ensure uniform illumination, while high numerical aperture achieves high resolution. Combined with software for 3D reconstruction analysis, it guarantees chip quality.

② Packaging and Testing: Multi-angle imaging comprehensively captures package images, inspecting pin bonding, plastic encapsulation, and markings. This enhances inspection speed and accuracy while optimizing production processes.

3. Automotive Component Manufacturing

① Engine Component Inspection: Performs dimensional measurement and surface defect detection. Ensures high-precision measurement of critical dimensions, suppresses metal reflections, detects internal flaws, and elevates engine quality.

② Body Panel Inspection: Enables large-area, high-resolution surface inspection. Highlights minute surface irregularities to assess weld quality and performs color consistency checks, enhancing vehicle appearance.

4. Medical Device Industry

① Medical Catheter Inspection: Transmits light along the axis for internal visualization, rotates to capture images for smoothness and cleanliness checks, and performs non-contact outer wall inspection to ensure catheter safety.

② Medical Equipment Component Assembly Inspection: Enables precise positioning and alignment in confined spaces, monitors spatial relationships in real time, records dynamic calibration data, and safeguards equipment performance.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION