What is an FA lens?

FA lenses are industrial-grade optical components specifically designed for factory automation and machine vision systems, falling under the category of “fixed-focus lenses.” Their defining characteristic is a fixed focal length—focus cannot be adjusted by rotating the lens (e.g., the zoom ring found on a 16-35mm zoom lens is absent in FA lenses). Changes in framing require moving the camera position or swapping lenses with different focal lengths. This feature provides high stability and low distortion advantages in industrial inspection and precision measurement applications, contrasting with the continuous focus adjustment flexibility of consumer-grade zoom lenses.

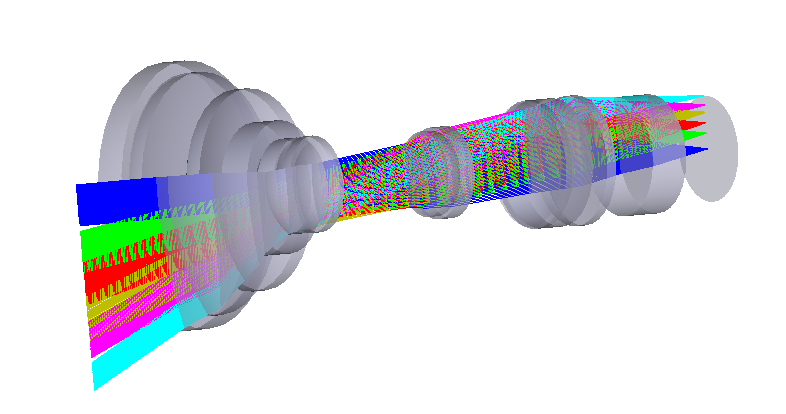

FA Lens Optical Principles and Structural Analysis

1. Objective and Eyepiece Systems: The objective lens (front lens group) converges reflected light from the object onto the image plane, while the eyepiece (rear lens group) magnifies the image and corrects aberrations. For example, dual telecentric lenses employ a “object-side + image-side” dual parallel optical path design, maintaining constant magnification across the depth of field and resolving the parallax issue of traditional lenses where “near objects appear larger than distant ones.”

2. Aberration Control: Spherical/aspherical lens combinations, convex-concave lens matching, and aperture position adjustments correct spherical aberration, coma, astigmatism, chromatic aberration, and distortion. Aspherical lenses reduce edge light shift and minimize barrel distortion; multi-layer coating technology enhances infrared/visible light transmission and eliminates focal plane shift.

3. Depth of Field and Focus Depth: Depth of field refers to the range of distances in front of and behind the subject that appear sharp in an image. It is influenced by aperture (F-number), focal length, and object distance—a smaller aperture (higher F-number), shorter focal length, and greater object distance result in a larger depth of field. Industrial applications often leverage this characteristic to capture images of uneven component surfaces.

The Relationship and Differences Between FA Lenses and Prime/Zoom Lenses

FA lenses strictly fall under the category of prime lenses, with their “fixed focal length” characteristic stemming from industrial applications' stringent demands for consistent imaging. In contrast, zoom lenses achieve continuous focal length adjustment (e.g., 24-70mm) through moving lens groups. However, the coordinated movement of multiple lens elements often compromises image quality, leading to issues such as reduced edge resolution and increased chromatic aberration. While sacrificing zoom flexibility, FA lenses deliver superior optical performance (e.g., MTF curves, distortion control), making them particularly well-suited for high-precision measurement applications.

Industrial Application Suitability:

1. Sensor Size Matching: The lens imaging plane (sensor size) must be ≥ the camera's image sensor dimensions (e.g., 2/3-inch, 1-inch) to prevent vignetting or black borders. For example, C-mount FA lenses are typically paired with 2/3-inch cameras to ensure edge-to-edge image quality.

2. Focal Length Calculation: Determine the required focal length using the formula f = 1 + PMAG × WD, where PMAG is the optical magnification. This calculation accounts for the field of view (FOV), working distance (WD), and camera sensor size. For instance, a 1-inch sensor camera at a 300mm working distance with a 120mm FOV height requires a lens with approximately 22mm focal length.

3. Telecentric Design: Object-side telecentric lenses accept only parallel object-side light rays, eliminating “near-large, far-small” distortion. Image-side telecentric lenses ensure uniform illumination across the image plane. Dual-telecentric lenses combine both advantages, offering 20-30% greater depth of field than standard lenses. They are ideal for imaging thick objects (e.g., LCD panel inspection).

FA Lenses in Industrial Applications

-

High-precision measurement: For applications such as electronic component dimensional inspection and screw thread defect identification, relying on low distortion (<0.1%) and high resolution (>200 lines per millimeter).

-

High-Speed Dynamic Imaging: Enables continuous scanning of moving objects with line-scan cameras. Requires a large aperture (e.g., F1.4) to increase light intake, ensuring clear imaging in low-light conditions.

-

Multi-band Adaptation: Specialized lenses for visible light, infrared, and even X-ray bands achieve high transmission across broad wavelengths and consistent focal plane alignment through the use of specialized glass materials (such as ZnSe and CaF₂) and advanced coating technologies.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com