I. Equipment Preparation and Basic Operations

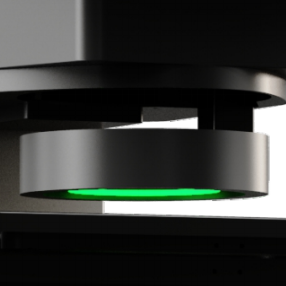

1. Power-On and Warm-Up: After turning on the power, allow the device to warm up for 5 minutes to ensure the optical system and sensors stabilize. The Pumis IMAGE3 series supports one-touch startup. During warm-up, perform workbench calibration simultaneously by adjusting the measurement platform to a level state using a spirit level to prevent measurement errors.

2. Environmental Requirements: Place the device in a vibration-free environment with temperatures between 0-45°C (32-77°F) and humidity ≤85% RH. Avoid direct exposure to strong light or electronic interference to ensure measurement accuracy.

II. Workpiece Placement and Clamping

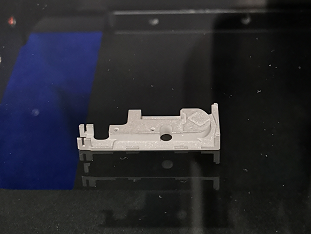

1. Workpiece Positioning: Place the workpiece to be measured steadily at the center of the measurement platform and secure it with fixtures (e.g., use vacuum cups for small precision screws). The POMEAS IMAGE3 Pro-H supports 3D measurement within 300×200×75mm. Allow 10%-20% clearance for workpiece dimensions to avoid exceeding the measurement range.

2. Light Source Adjustment: Select surface light or transmitted light based on the workpiece material. Use the software to adjust brightness until the image is clear and glare-free. For example, metal parts require high-brightness light sources, while transparent plastic parts require low-angle transmitted light.

III. Measurement Mode Selection and Parameter Settings

1. Mode Selection: For 2D planar measurement (e.g., chip pins, circuit boards), select modes like “Line Measurement” or “Circle Measurement.” Utilize dual telecentric lenses to achieve ±(3.5+L/50)μm accuracy. For 3D contour scanning: Activate the Z-axis height measurement module. Combined with contour scanning sensor technology, this achieves 0.1μm-level precision.

2. Parameter Configuration: Adjust resolution, measurement units (μm/mm), edge extraction algorithms, and other parameters in the software settings interface. POMEAS equipment supports sub-pixel processing, automatically identifying burrs/defects and excluding outliers.

IV. Image Acquisition and Data Processing

1. Auto-Focus and Image Capture: Ensures full-field clarity of workpieces through motorized Z-axis auto-focus. The POMEAS IMAGE3 series supports “one-touch measurement,” completing inspections of 100 locations within 1 second, ideal for batch measurement of multiple workpieces.

2. Feature Recognition and Analysis: The software automatically identifies features such as points, lines, circles, and angles, supporting virtual line/point measurements. For example, arc measurements utilize the three-point positioning method, outputting parameters like center distance and maximum/minimum dimensions. Data can be exported as Excel reports or CAD drawings.

V. Precautions and Maintenance

1. Operating Procedures: Avoid manually adjusting calibrated coordinate systems and prohibit arbitrary changes to equipment parameters. Keep workpieces stationary during measurement to minimize vibration interference.

2. Maintenance: Regularly clean lenses and sensors using dedicated lens-cleaning paper. Perform monthly calibration verification using standard parts to verify equipment accuracy.

1. Intelligent Recognition: AI algorithms automatically identify workpiece position and orientation, supporting arbitrary placement to reduce setup time.

2. Multi-Sensor Fusion: The IMAGE3 Max series integrates laser profilometers with microscopic systems, enabling seamless switching between 2D and 3D measurement.

3. Remote Support: The POMEAS Cloud platform enables remote diagnostics of device status and software algorithm updates.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com