Precise Selection Guide for Variable-Focus Lenses and Zoom Lenses

In the field of machine vision inspection, lenses serve as the core components of optical systems, with their performance directly impacting imaging quality and detection accuracy. However, the terms “variable magnification lens” and “zoom lens” are often confused in the market. A variable magnification lens magnifies products by adjusting magnification levels to observe details, whereas a zoom lens provides different fields of view at a specific working distance or similar fields of view at different working distances.

I. Differences in Optical Essence: From “Magnification Adjustment” to “Focal Length Transformation”

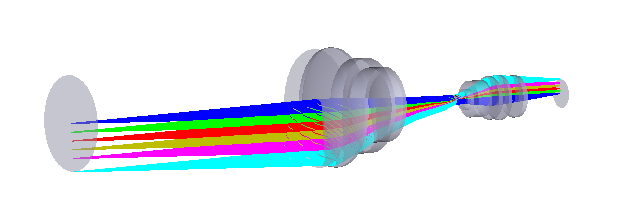

1. Zoom Lens

By continuously adjusting the distance between the objective lens and eyepiece, magnification levels can be varied. Its core feature lies in the “variable magnification ratio”—for example, a 10:1 zoom lens allows continuous magnification adjustment from 10x to 100x. This design enables precise magnification of local details without moving the object under examination, making it ideal for scenarios requiring high-magnification precision inspection.

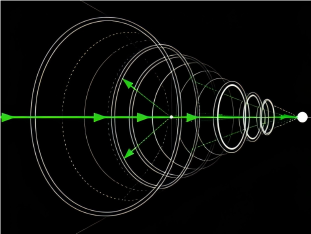

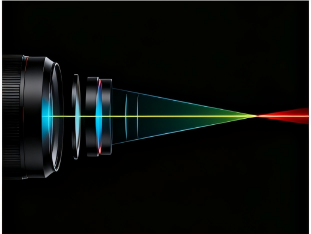

2. Variable Lens

Zoom lenses achieve continuous focal length adjustment by altering the relative positions of internal lens elements. This mechanism fundamentally changes the field of view (FOV) by adjusting the focal length—for example, enabling seamless zooming from a 2.8mm wide-angle to a 12mm telephoto. This capability makes them exceptionally effective for scanning expansive scenes and tracking moving subjects. However, note that refocusing is required during zooming to maintain image sharpness.

II. Real-World Scenario Comparison

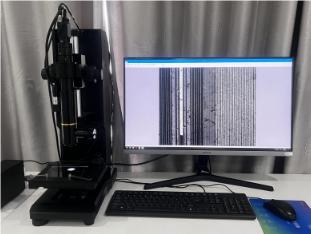

Case 1: Electronic Component Defect Detection—The Absolute Advantage of Variable Magnification Lenses

In semiconductor wafer inspection, scratches as small as 5μm must be detected within a 0.1mm² area. Using a 10:1 zoom lens paired with a 1/1.8" large-format camera achieves: - Optical resolution of 2μm, meeting sub-pixel inspection requirements; - Precise depth-of-field control, ensuring micron-level Z-axis positioning accuracy; - Multi-area inspection without moving the stage, enhancing inspection efficiency.

Case 2: Intelligent Warehouse Logistics Monitoring—Adaptability of Zoom Lenses to Scenarios

For monitoring a 30-meter-long logistics corridor, simultaneous coverage is required for both close-range shelf label recognition (demanding a wide-angle lens) and distant forklift tracking (requiring a telephoto lens). Selecting a 2.8-12mm zoom lens paired with a 4K camera enables: - A single lens to switch between a 45° wide-angle and 15° telephoto field of view; - Intelligent patrol monitoring via motorized zoom; - Continuous clear imaging maintained through autofocus technology.

III. Guide to Avoiding Pitfalls in Model Selection

01. Prioritize detection requirements: For high-magnification detail observation (e.g., 0.1mm-level defect detection), prioritize variable magnification lenses; for wide-area coverage (e.g., warehouse panoramic monitoring), zoom lenses offer greater cost-effectiveness.

02. Focus on optical stability metrics: For variable magnification lenses, prioritize evaluating MTF curve consistency across different magnification levels and distortion control capability. For zoom lenses, emphasize repeatability accuracy during motorized zooming and autofocus response speed.

03. Validate in real-world scenarios: Conduct three-dimensional testing in laboratory environments measuring “magnification/zoom - clarity - depth of field.” Simulate production conditions to verify lens stability under factors like vibration and temperature fluctuations.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com