In the fields of smart manufacturing and precision inspection, industrial zoom lenses have become the core lens modules for precision instruments such as flash measurement systems, image measuring machines, and composite contour measuring devices, thanks to their dynamic zoom capabilities and wide magnification range (0.58x-14x). For example, POMEAS industrial zoom lenses have become a preferred choice among equipment manufacturers due to their advantages: 2μm-level resolution, 4K ultra-high-definition imaging quality, and millisecond-level magnification switching speed.

I. Core Advantages of Industrial Variable Magnification Lenses

1. Ultra-wide magnification dynamic adjustment:

Continuous stepless zoom capability from 0.58x to 14x enables seamless switching between macro scene positioning (e.g., capturing large-scale workpiece contours) and microscopic defect magnification (e.g., detecting 0.01mm-level gold finger defects), boosting single-pass inspection efficiency by over 40%.

2. 4K UHD Imaging:

Featuring high-transmittance optical lenses and low-distortion design, paired with a 4K sensor to achieve 2μm-level resolution imaging. Demonstrates exceptional detail capture in scenarios like pixel-level defect detection on OLED screens and micron-level scratch identification on wafers.

3. Intelligent magnification switching system:

Enables millisecond-level magnification switching via an electric zoom mechanism. This facilitates rapid multi-area scanning and 3D topography reconstruction in composite profile measurement equipment, meeting the high-speed inspection demands of automated production lines.

II. Collaborative Application of Equipment

- Flash Inspection System Application: On high-speed production lines, industrial zoom lenses achieve efficient inspection at dozens of times per second through rapid magnification switching and high-frequency imaging triggers. Combined with the system's autofocus and image analysis algorithms, it accurately identifies defects such as solder joint defects and screw hole dimensional deviations.

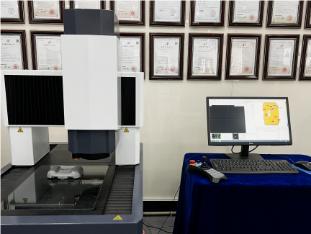

- Image Measuring Instrument Application: Within two-dimensional measurement equipment, the industrial zoom lens offers continuous magnification adjustment from 0.58x to 14x. This enables simultaneous scanning of the entire workpiece contour and precise measurement of critical dimensions (such as curvature radius and center thickness), with measurement errors controlled within 0.01mm.

- Compound Profile Measurement Equipment: In three-dimensional topography inspection, the large depth-of-field design and high-resolution imaging capabilities of industrial zoom lenses enable rapid non-contact measurement of complex curved-surface components. This equipment meets inspection demands in high-precision manufacturing sectors such as aerospace and medical devices.

III. Industry Applications

- Semiconductor Industry: In wafer defect inspection, 14x high magnification combined with ±1μm positioning accuracy enables detection of 0.3μm-level scratches and particle contamination. Supplemented by motorized zoom functionality for rapid multi-area scanning, this significantly reduces material loss during wafer dicing.

- Automotive Manufacturing: In automotive component inspection, dynamic zoom capabilities enable comprehensive coverage from capturing large sheet metal part contours to detecting minute cracks, boosting inspection efficiency by over 3 times and increasing yield rates by 15%.

- Consumer Electronics: In OLED screen inspection, its ultra-wide magnification and low distortion characteristics simultaneously meet the demands for large-area uniformity testing and pixel-level defect localization, ensuring consistent color temperature and high yield rates.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com