Industrial Zoom Lenses: The Optical Solution for Multi-Industry Inspection

In the field of industrial inspection, striking a balance between precision and efficiency remains a core imperative. With its two key features—rapid magnification switching and an ultra-wide optical zoom range of 0.58x to 14x—POMEAS industrial zoom lenses are emerging as the critical tool for overcoming inspection bottlenecks across industries such as hardware and electronics, wafer and semiconductor manufacturing, optical lens production, and plastics processing.

I. Technical Features: Dynamic Magnification Switching and Ultra-Wide Magnification Range

The core advantage of industrial zoom lens lies in their dynamic optical adjustment capability. Through precision optical structure design, they achieve continuous varifocal from 0.58x to 14x, meeting all-scenario demands—from rapid macro scene positioning to precise micro detail magnification. Compared to traditional fixed-magnification lenses, their “rapid magnification switching” feature boosts inspection efficiency by over 40%. For instance, in hardware and electronics production lines, operators can complete the entire inspection process—from scanning the product's overall appearance to magnifying defects down to 0.1mm—without changing lenses, significantly shortening the inspection cycle.

II. Industry Applications: Precisely Addressing Testing Pain Points Across Four Key Domains

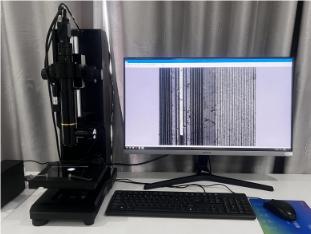

1. Hardware & Electronics: Dual Breakthroughs in Flaw Detection and Dimensional Measurement

In the hardware and electronics industry, product appearance defects (such as scratches and dents) and dimensional accuracy (such as ±0.01mm tolerance control) are two core inspection requirements. Industrial zoom lenses achieve high magnification (up to 14x) to clearly capture 0.05mm-level defects on metal surfaces, while autofocus functionality enables precise defect localization. For dimensional measurement, integration with industrial cameras and image processing algorithms enables rapid non-contact measurement. This reduces individual part inspection time from 30 seconds using traditional methods to just 5 seconds, boosting yield rates by 15%.

2. Wafer Semiconductor: Dial Scratch Detection and Laser Cutting Assistance

Wafer manufacturing demands extremely high surface cleanliness, where even 0.3μm-level scratches can impact chip yield rates. Industrial zoom lenses serve as the “microscopic eyes” in wafer inspection: with 14x high magnification combined with ring lighting, they clearly identify micron-level scratches, particle contamination, and other defects on the wafer surface. During laser cutting, the lenses' precise magnification adjustment assists the laser head in accurately positioning the cutting path, ensuring cutting precision of ±1μm and significantly reducing material loss during wafer dicing.

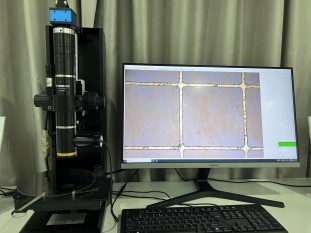

3. Optical Lenses: Surface Defect Detection and 2D Measurement

The optical lens industry demands stringent requirements for surface finish and geometric precision. Industrial zoom lenses paired with coaxial light sources and industrial cameras enable sub-micron-level inspection of lens surface defects such as pitting and watermarks. When integrated into 2D inspection equipment, continuous magnification adjustment from 0.58x to 14x enables simultaneous precise measurement of critical dimensions like lens curvature radius and center thickness. For instance, in eyeglass lens production, this solution boosts inspection efficiency by 3 times while controlling measurement errors within 0.01mm.

4. Plastics Industry: Appearance Inspection and Molding Defect Analysis

Plastic products are prone to defects such as sink marks, flow marks, and bubbles during injection molding. Industrial zoom lenses enable rapid inspection workflows through wide magnification adjustment—from scanning the entire product surface (0.58x low magnification) to high-magnification defect examination (14x). In automotive interior component inspection, these lenses accurately identify sink marks as small as 0.2mm and generate defect distribution heatmaps via image analysis software, providing data-driven insights for process optimization.

With the advancement of Industry 4.0 and smart manufacturing, industrial zoom lenses are evolving toward intelligent and integrated solutions. By integrating AI vision algorithms, future lenses will enable automatic defect identification and classification. Through coordination with robotic arms, AGVs, and other equipment, they can establish fully automated inspection lines. With their exceptional optical performance and flexible application adaptability, POMEAS industrial zoom lenses are becoming indispensable “vision eyes” in precision manufacturing, continuously driving industrial inspection toward greater efficiency and accuracy.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com