In the wave of smart manufacturing, industrial zoom lenses have become core visual tools for precision inspection, laser processing, scientific research, and education due to their dynamic optical adjustment capabilities. However, faced with the overwhelming variety of lens models on the market, accurately selecting the right lens based on actual needs presents a real challenge for enterprises. Drawing on years of industry experience from the POMEAS technical team, we have developed a systematic decision-making framework for selecting industrial zoom lenses. This framework addresses three key dimensions: practical application scenarios, core parameter analysis, and solution configuration logic.

I. Practical Application Scenarios: The Starting Point for Demand-Driven Selection

The selection of industrial zoom lenses must be anchored to specific application scenarios, as different industries exhibit significant variations in their optical performance requirements:

- Wafer Cutting Scenario: In semiconductor manufacturing, wafer cutting requires both high-magnification defect detection and laser positioning accuracy. Industrial zoom lenses must provide over 14x magnification capability, paired with ring lights to achieve clear imaging of micron-level scratches and particle contamination. Simultaneously, precise magnification adjustment assists the laser head in achieving ±1μm-level cutting path positioning.

- PCB Inspection Scenario: In the electronics manufacturing sector, detecting defects such as solder joint issues and open/short circuits on PCBs requires balancing inspection efficiency with imaging quality. Industrial zoom lenses, featuring continuous varifocal capabilities from 0.58x to 14x, enable rapid completion of the entire inspection process—from full-board scanning to localized solder joint magnification. Combined with autofocus functionality, they achieve precise localization of defects.

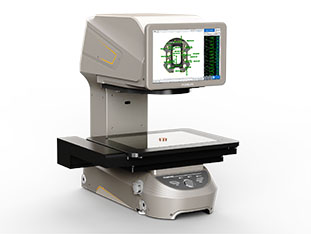

- Precision Component Dimension Measurement Applications: In high-precision manufacturing sectors such as aerospace and medical devices, industrial zoom lenses must meet sub-micron measurement requirements. When paired with 2D measuring equipment or flash measurement instruments, they enable rapid non-contact dimensional measurement with errors controlled within 0.01mm. Their wide depth-of-field design accommodates inspection needs for components of varying thicknesses.

II. Core Parameter Analysis: Quantitative Decision-Making Basis for Technical Indicators

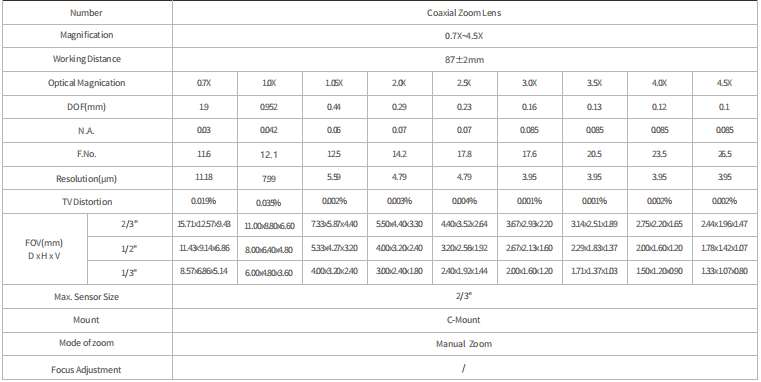

The selection of industrial zoom lenses must be based on a scientific understanding of key parameters. The following six core parameters form the essential dimensions for technical decision-making:

- Magnification Range: The wide magnification range of 0.58x-14x covers all scenarios from macro scene positioning to microscopic detail magnification. Select the magnification range based on the specific size characteristics of the inspection object. For example, wafer inspection requires high magnification (≥10x), while large-sized part inspection can utilize lenses with a lower magnification range.

- Working distance: Refers to the distance from the front of the lens to the object being measured, directly affecting the spatial adaptability of the inspection equipment. In automated production lines, the appropriate working distance parameters must be determined comprehensively based on factors such as the operating space of robotic arms and the dimensions of the inspection platform.

- Depth of field: The maximum range within which the lens can be moved while maintaining clear imaging. In three-dimensional topography inspection scenarios, a lens with a large depth of field reduces the number of focus adjustments required, thereby improving inspection efficiency.

- Numerical Aperture (NA): Directly impacts a lens's resolution and imaging brightness. High NA lenses deliver superior resolution, making them ideal for detecting minute defects; low NA lenses are suited for scenarios requiring a wider field of view.

- Resolution: Refers to the smallest detail size that a lens can clearly distinguish. In precision inspection scenarios, lenses with appropriate resolution must be selected based on the feature dimensions of the inspection object. For example, wafer inspection requires a resolution of ≥5μm.

- Interface Type: Must be compatible with interfaces of industrial cameras, lighting systems, and other equipment. Common interface types include C-mount and CS-mount; the appropriate interface should be selected based on existing equipment specifications.

III. Solution Integration Logic: Collaborative Optimization Strategy for System Integration

The selection of industrial zoom lenses must be coordinated with the overall architecture of the inspection solution, as the adaptation logic varies significantly across different inspection equipment:

- Two-dimensional measurement equipment: When pairing with two-dimensional measurement equipment, high-resolution, low-distortion industrial zoom lenses must be selected to achieve sub-micron dimensional measurement accuracy. Concurrently, consideration must be given to matching the lens's magnification range with the measurement device's field of view.

- Simplified Vision Solution: For cost-sensitive applications, a basic vision inspection system can be constructed using an industrial zoom lens paired with an industrial camera and LED lighting. This solution requires particular attention to the lens's zoom speed and imaging stability to ensure production line inspection efficiency.

- Flash-measurement instrument: In high-speed inspection scenarios, industrial zoom lenses must be co-engineered with the instrument's trigger mode, exposure time, and other parameters. Through rapid zoom switching and high-frequency trigger imaging, it achieves high-speed inspection capabilities of dozens of measurements per second.

IV. Industrial Zoom Lens Selection Guide

1. Identify the core requirements of the inspection scenario (e.g., object dimensions, accuracy specifications, inspection efficiency, etc.);

2. Determine technical specifications for key parameters such as magnification range, working distance, and depth of field based on these requirements;

3. Select compatible interfaces by considering existing hardware conditions like inspection equipment interface types and light source types;

4. Choose appropriate optical configuration combinations based on budget constraints and system integration needs.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com