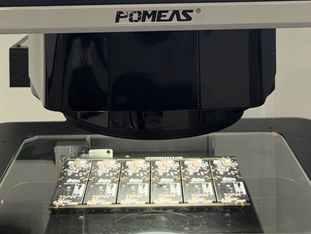

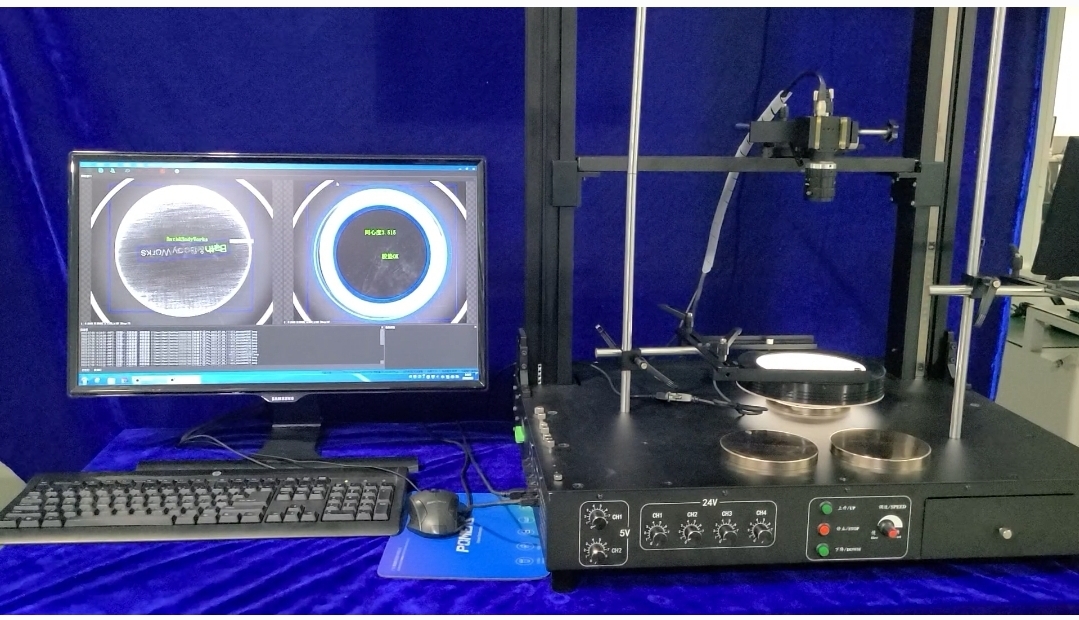

The Ultimate Guide to Optimal FA Lens and Circuit Board Inspection Solutions

As electronic components become increasingly miniaturized and integrated, traditional manual inspection methods struggle to meet the demands of high-precision, high-efficiency production. Machine vision inspection technology has gradually emerged as the core method for circuit board quality control, where the selection and matching of FA lenses directly determine the quality of inspection results.

I. Challenges and Requirements in Circuit Board Inspection

1. High Precision Requirements: Modern circuit board components feature minute dimensions and fine solder joint spacing, demanding lenses with high resolution and low distortion characteristics.

2. High-Speed Detection: Production lines operate at rapid pace, demanding fast processing speeds from vision systems. Lenses must deliver superior light throughput and transmission efficiency.

3. Complex Scenarios: Circuit board surfaces feature diverse materials and reflective properties, necessitating lenses that effectively suppress glare and artifacts.

4. Stability Requirements: Continuous operation in industrial environments over extended periods demands optical systems with exceptional environmental adaptability and reliability.

II. Key Parameters and Selection Criteria for FA Lenses

1. Resolution Matching: The lens resolution should exceed the sensor resolution to ensure discernibility of the finest circuit features. POMEAS FA lenses utilize premium optical glass and precision grinding technology to deliver outstanding central and edge resolution, guaranteeing sharp imaging across the entire field of view.

2. Working Distance and Field of View: Select the appropriate working distance and field of view based on the inspection target and equipment spatial layout. The POMEAS series lenses offer multiple specification options to meet diverse requirements ranging from overall inspection to detailed local inspection.

3. Distortion Control: Optical distortion can compromise measurement accuracy. The POMEAS FA lens employs a specialized optical design that minimizes distortion to an extremely low level, ensuring image geometric fidelity and providing the foundation for precise measurements.

4. Depth of Field Requirements: For circuit boards with uneven surface heights, sufficient depth of field is required to ensure clear imaging across the entire test area. POMEAS's large depth-of-field lens series maintains sharp imaging across different height planes, reducing the frequency of refocusing.

5. Spectral Characteristics: Different inspection tasks may require illumination at specific wavelengths. The POMEAS FA lens is optimized for the visible light spectrum while also offering a near-infrared version to accommodate diverse lighting environments.

The adoption of POMEAS FA high-resolution lenses in the circuit board solder joint inspection system has successfully elevated detection accuracy to the micrometer level, reduced misjudgment rates, accelerated inspection speed, and substantially improved production efficiency and product quality.

Selecting the appropriate FA lens is critical to building an efficient PCB inspection system. By thoroughly understanding inspection requirements, scientifically selecting lens parameters, and leveraging the superior performance of POMEAS FA lenses, enterprises can construct stable and reliable vision inspection systems that significantly enhance product quality and production efficiency.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com