Five Core Advantages of Image Dimension Measurement Instruments in Circuit Board Inspection

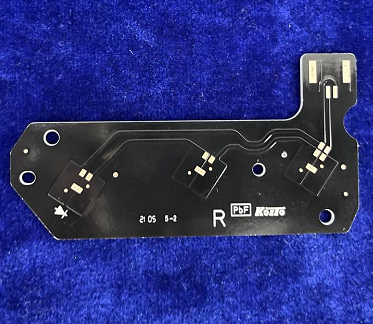

In modern electronics manufacturing, circuit board quality control is of paramount importance. Even the slightest dimensional deviation can lead to circuit board malfunction or complete failure. Traditional inspection methods struggle to meet increasingly precise manufacturing demands, while the advent of image-based dimensional measurement instruments has revolutionized circuit board inspection.

High-precision Measurement Ensures Product Quality

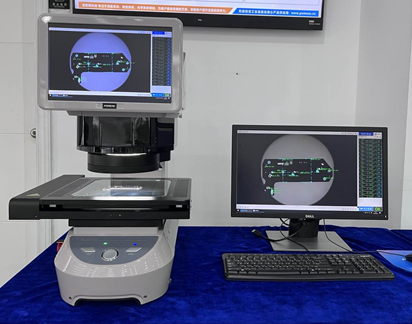

The POMEAS Image Dimension Measuring Instrument employs an advanced optical system and image processing algorithms to achieve micron-level precision measurements. During circuit board inspection, the instrument accurately captures critical parameters such as pad dimensions, trace widths, and spacing, ensuring every detail complies with design specifications. This level of accuracy far surpasses traditional manual measurement methods like calipers and microscopes, significantly reducing quality risks caused by measurement errors.

Non-contact Measurement Prevents Product Damage

Unlike traditional contact-based measurement methods, the POMEAS Image Dimension Measuring Instrument employs a fully non-contact measurement approach. This feature is particularly well-suited for measuring delicate and fragile circuit boards, preventing potential scratches, deformation, or electrostatic damage during the measurement process. Additionally, non-contact measurement enables inspection of circuit boards under special conditions such as high temperatures or susceptibility to deformation, thereby expanding the scope of quality control coverage.

High-efficiency Inspection Boosts Production Efficiency

The POMEAS Image Dimension Measuring Instrument features automated measurement capabilities, completing multiple parameter measurements within seconds to significantly enhance inspection efficiency. The instrument automatically identifies measurement features, batch-processes inspection data, and generates detailed inspection reports. This highly efficient inspection method enables enterprises to substantially increase production throughput while maintaining high-quality standards and reducing labor costs.

Comprehensive Data Management Enables Quality Traceability

The instrument features robust data management capabilities, enabling storage of all measurement results and creation of comprehensive product quality records. Through POMEAS' professional analysis software, users can perform trend analysis on historical data, promptly identify abnormal fluctuations in production processes, and implement preventive quality control. This comprehensive data management capability provides a solid data foundation for enterprises to implement lean production and continuous improvement.

Simple Operation Lowers The Barrier To Entry

The POMEAS Image Dimension Measuring Instrument features a user-friendly design with an intuitive interface, enabling even non-technical personnel to master it quickly. The instrument offers intelligent functions such as auto-focus and auto-recognition, minimizing subjective human error. Additionally, POMEAS provides comprehensive technical training and after-sales service to ensure users can fully leverage the instrument's capabilities and achieve a rapid return on investment.

In today's fiercely competitive electronics manufacturing landscape, adopting advanced inspection technologies is crucial for businesses to maintain a competitive edge. The POMEAS Image Dimension Measuring Instrument delivers comprehensive quality assurance solutions for PCB manufacturers with its exceptional precision, efficiency, and reliability. By implementing this advanced tool, companies can not only enhance product quality but also optimize production processes and reduce overall costs, ultimately gaining greater competitive advantage in the marketplace.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com