Machine vision light sources play a crucial role in vision inspection solutions. They not only provide illumination for the object being inspected, but also enhance the contrast between the target and the background in the image through rational design, thus improving the accuracy and reliability of the inspection.

Light Source Characterization:

1、High brightness: provide enough light to make the image clearer.

2、Low energy consumption: reduce the system operating costs.

3、Long life: reduce the number of times to replace the light source and maintenance costs.

4、Dimmable light: realize the adjustment of light intensity by adjusting the current, adapt to the light demand in different scenes.

5、No ultraviolet rays: avoid damage to the detected objects.

6、Small size: easy to integrate into a variety of equipment.

Application scenarios and configuration methods:

1. Illuminate the detected object: the main role of the light source is to illuminate the detected object to ensure that the image acquisition equipment can capture clear images.

2. Enhance contrast: Through reasonable light design, the contrast between the target and the background in the image is enhanced, so that the machine vision system can more clearly identify the contours, edges, defects and other features of the object.

3. Customized light source type: customized according to the characteristics of the inspection object. For example, for products made of transparent or translucent materials, infrared or ultraviolet light with strong penetration can be selected; for products made of metal or dark-colored materials, high-brightness LED light source or laser light source can be selected.

4. Adjust the lighting angle: by changing the angle of light source illumination, it can reduce the reflection interference and highlight the object features. For example, back lighting is used to emphasize the outline of the product, and side lighting is suitable for detecting the side features of the object.

5. Diversified configuration: ring light source can highlight the three-dimensional information of the object, and coaxial light source can eliminate reflections. These features make the machine vision system flexible in choosing the light source configuration according to different inspection needs.

Optimize detection efficiency and performance:

(1) Improvement of brightness and response time: In high-speed production lines, by optimizing the brightness and response time of the light source, the image acquisition and processing speed can be improved to meet the needs of high-speed inspection.

(2) Enhance anti-interference ability: machine vision system may face various complex environmental conditions in practical application. By choosing suitable light source and configuration mode, the anti-interference ability of the system can be enhanced so that it can maintain stable performance under various environmental conditions.

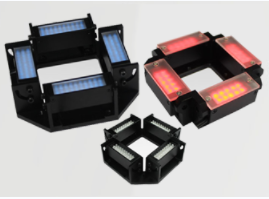

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com