Against the backdrop of today's increasingly stringent requirements for precision and efficiency in industrial production, POMEAS' newly launched In-Line Digital Diameter Measuring Instrument (IDM) shines like a bright new star at the forefront of measurement technology. With its excellent performance and advanced technology, this innovative product provides a reliable solution for the precision measurement needs of various industries.

Advanced technology, casting excellent quality

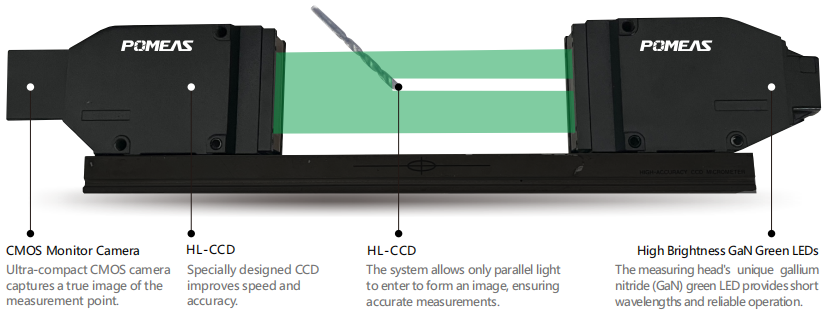

POMEAS In-Line Digital Diameter Measuring Instrument incorporates a number of advanced technologies to realize the perfect combination of high speed and high accuracy. The advanced optical technology acts as a precise “eye” to keenly capture the subtle dimensional changes of the measured object. The high-brightness green LED light source not only provides stable and uniform illumination, but also ensures that the measurement process is not interfered by external light, making the measurement results more accurate and reliable.

The telecentric lens on the receiving end acts as a high-precision “magnifying glass”, which effectively reduces measurement errors due to changes in viewing angle and ensures consistent measurement results regardless of the position of the object being measured. The HL-CCD (High Brightness Linear Charge Coupled Device) is like a highly efficient “data collector”, which quickly and accurately converts optical signals into digital signals, providing a solid foundation for subsequent data analysis and processing.

High-speed measurement for improved productivity

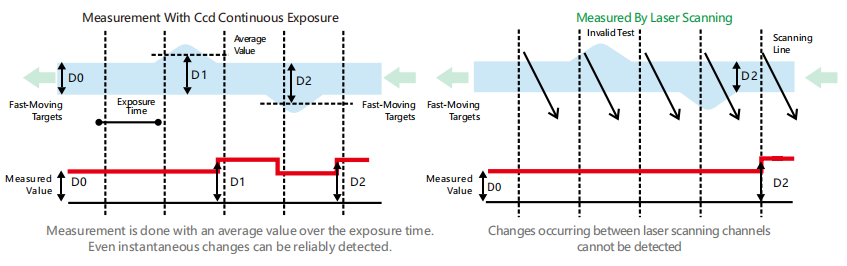

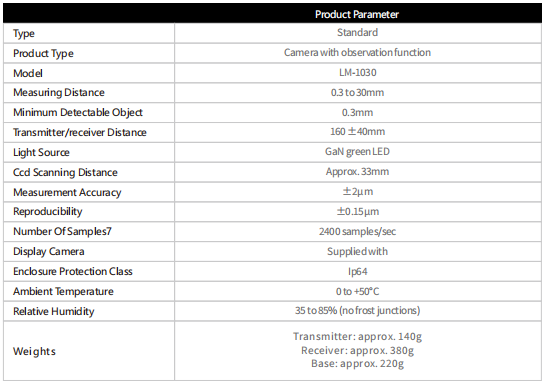

In fast-paced industrial production, time is money. With up to 2400 samples/second, POMEAS in-line digital calibrators can take multiple measurements of the object being measured in a split second, ensuring that products on the production line are inspected in a timely and accurate manner. Whether it's high-speed cable production, precision machining, or fast-flowing pipe manufacturing, this gauge can handle it all with ease, ensuring the efficient operation of the production process.

High precision measurements to ensure product quality

Accuracy is the core value of measuring instruments. With ±0.06um reproducibility and ±2um measurement accuracy, POMEAS in-line digital calibrator can accurately measure the diameter, radius and other dimensional parameters of the object under test, providing a reliable basis for strict product quality control. In electronic components manufacturing, optical lens processing and other industries that require high precision, this diameter measuring instrument can help companies to ensure that each product meets the strict quality standards, to avoid the production of defective products due to dimensional deviations.

Wide range of applications to meet diverse needs

The excellent performance of POMEAS on-line digital calipers makes them have a wide range of applications in many fields. In the wire and cable industry, it can monitor the outer diameter of the cable in real time to ensure that the product meets the standard specifications, and improve the consistency and reliability of the product; in the field of machinery manufacturing, it can accurately measure the dimensions of all kinds of shafts and holes, and provide a strong support for the precision control of the machining process; in the production of plastic tubes, it can quickly detect the wall thickness and diameter of the tubes, and help enterprises to optimize the production process and improve the quality of the product. In plastic pipe production, it can quickly detect the wall thickness and diameter of the pipe, helping enterprises optimize the production process and improve product quality.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com