In industrial production, plating thickness measurement has always been a highly concerned and challenging link. How to accurately and efficiently measure the thickness of plating layer without damaging the surface of the product has become a common problem faced by many enterprises and technicians. In recent years, with the advancement of science and technology, white light interference technology has emerged in the field of plating thickness measurement with its high precision and non-contact measurement features, among which POMEAS White Light Interference 3D Profiler has won wide recognition in the market with its excellent performance.

Principle of White Light Interference Technology

White light interference technology is a measurement method based on the volatility of light and the principle of interference. When two or more coherent light waves meet in certain regions of space, they reinforce or cancel each other, forming light and dark interference fringes. The distribution and shape of these interference fringes are related to the wavelength of the light waves, the phase difference, and the location of the meeting point. By precisely controlling the light source and measuring the interference fringes, accurate measurement of the surface topography and coating thickness of an object can be realized.

Advantages of POMEAS White Light Interference 3D Profiler

1. High precision measurement: POMEAS White Light Interference 3D Profiler adopts advanced white light interference technology, which is capable of realizing nanometer level measurement accuracy and meets the demand of high precision coating measurement.

2. Non-contact Measurement: This technology measures by optical principle without direct contact with the measured object, thus avoiding scratches, deformation and other problems caused by contact, and ensuring the integrity of the product.

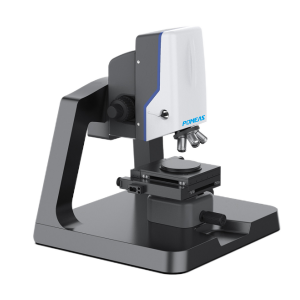

3. Real-time display and analysis: With compact overall design and advanced image processing technology, the instrument is capable of controlling the measurement image in real time on the workpiece table and displaying the three-dimensional results. At the same time, users can also easily select the cross-section for further analysis, which greatly improves the convenience and efficiency of measurement.

4. Powerful software function: POMEAS White Light Interference 3D Profiler is equipped with powerful software, which not only measures the coating thickness, but also scans the 3D profile of the whole product, and provides rich analyzing functions, such as surface roughness, morphological feature extraction, etc., which provides users with comprehensive data support.

POMEAS White Light Interference 3D Profiler has a wide range of applications in the field of plating measurement. It can be used to measure the thickness of plating layers on various metallic and non-metallic surfaces, such as electroplating, spraying and chemical plating. Meanwhile, the technology is also suitable for precision machining, semiconductor manufacturing, optical component inspection, etc., which provides a high-precision, non-destructive measurement means for these fields.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com