Industrial telecentric zoom lens: principle, parameters, fields of application

In modern industrial production and inspection, a high-quality imaging system is essential to ensure product quality, improve productivity, and achieve precise measurements. As an advanced optical device, industrial telecentric zoom lenses are widely used in many fields due to their unique principle and excellent performance.

Industrial telecentric zoom lens principle

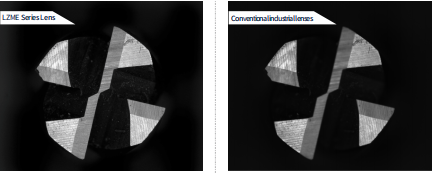

Industrial telecentric zoom lenses are based on a telecentric optical path design, the core principle of which is to eliminate parallax and perspective errors of conventional lenses. In telecentric lenses, the main light rays from the object side are incident parallel to the optical axis, making the image size independent of the object's proximity to the lens. This feature allows telecentric lenses to provide extreme precision and accuracy when measuring the size, shape and position of an object.

The zoom function, on the other hand, is realized by adjusting the combination of optical elements inside. By changing the distance between the lenses or using a movable lens group, it is possible to change the magnification by realizing continuous or segmented changes in the focal length without changing the object and image distances.

Industrial telecentric zoom lens parameters

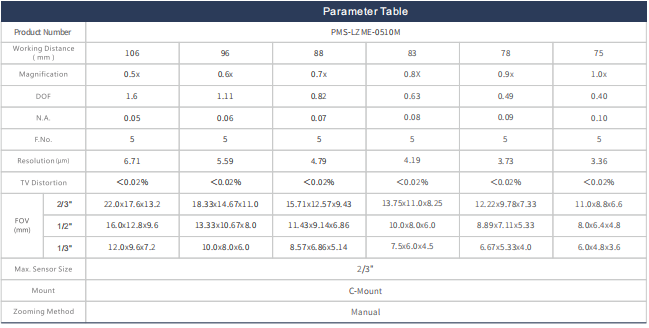

1, magnification: this is a key parameter to measure the lens zoom ability, usually expressed as a range, such as 0.5 × - 5 ×. A larger magnification range can meet more diverse inspection needs.

2, working distance: refers to the distance from the front of the lens to the object being measured. Different application scenarios require different working distances, the general industrial telecentric zoom lens has a wide range of working distance options.

3, resolution: reflects the smallest detail that the lens can distinguish, usually expressed in pairs of lines per millimeter (lp/mm). High-resolution lenses are able to capture a clearer, more detailed image.

4, depth of field: refers to the range of distance before and after the object in the imaging clear range. A greater depth of field can reduce the difficulty of focusing to some extent, improve detection efficiency.

5, aberration: refers to the degree of distortion of the image, industrial telecentric zoom lens usually has a very low aberration to ensure the accuracy of measurement and detection.

Areas of application

1、Industrial Inspection: It is used to detect tiny defects, dimensional accuracy and shape deviation in electronics manufacturing, automotive parts production and other industries. Telecentric zoom lens can provide clear and accurate images to help inspectors quickly find problems.

2、Machine vision: cooperate with automation equipment to realize the identification, positioning and classification of objects on the production line. For example, in the field of food packaging, drug dispensing, etc., to ensure product consistency and quality.

3、Measurement Measurement: In precision machining, mold manufacturing and other industries, it is used for high-precision measurement of the dimensions of parts. Its telecentric characteristic eliminates measurement errors and ensures the reliability of measurement results.

4、Scientific research field: In material science, biology and other research, it is used to observe and analyze the microstructure and sample characteristics.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com