In modern industrial production, efficient and accurate inspection technology is the key to improve product quality and productivity. Among them, 360° industrial inspection lens has become an important part of the machine vision system with its unique advantages and wide range of applications. In this paper, we will discuss in depth the characteristics of 360° industrial inspection lens, its working principle and its application in various fields.

360° industrial inspection lens features:

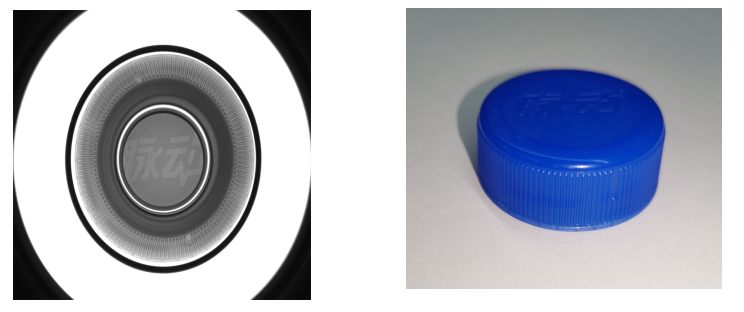

1、All-round detection capability: 360 ° industrial inspection lens is the most significant feature of its all-round detection capability. Whether it is the outer wall or the inner wall of the product, through this lens can be realized without dead angle detection. This feature makes it excellent in detecting workpieces with complex structures, such as bottle caps, water cups, screws and other small objects, can accurately identify defects hidden inside or outside.

2、High-efficiency: Compared with the traditional multi-group lens multi-group camera sub-angle shooting method, 360 ° industrial inspection lens can be a single camera lens to complete the acquisition of images, greatly simplifying the detection system and improve the detection efficiency. At the same time, this lens can also realize real-time detection, rapid feedback of the results, which helps companies to adjust the production process in a timely manner to reduce the rate of defective products.

3、High precision and high adaptability: 360 ° industrial inspection lens in the design and manufacturing focus on precision and adaptability. According to different inspection needs, the lens can adopt different optical structures and materials to achieve the best inspection results. In addition, through the special folding and reflecting optical path design, the lens can effectively reduce image distortion and improve the accuracy of the inspection results.

How 360° industrial inspection lenses work:

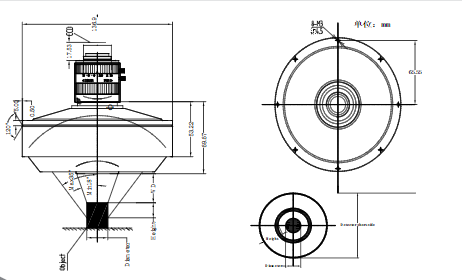

The working principle of 360° industrial inspection lens is mainly based on the imaging principle of fisheye lens or panoramic lens. During the inspection process, the lens is rotated or a special optical structure to achieve a comprehensive picture of the object. For the outer wall inspection lens, the principle of refraction is usually used to image the information on the outside of the ring of the object in a picture in the form of a circular crown; while the inner wall inspection lens unfolds and photographs the information on the inner wall through a special optical structure. Some of the 360° lenses also use 3D lens technology, which can accomplish three-dimensional inspection, further improving the accuracy and reliability of the inspection.

Application areas for 360° industrial inspection lenses:

1, Appearance Inspection: 360° outer wall inspection lens has a wide range of applications in the field of appearance inspection. It can be used to inspect the all-round appearance of products, such as batteries, medicine bottles, drink caps, plastic caps and other items of the surface character and defect recognition. Through high-definition imaging and precise identification technology, the lens can accurately capture the tiny defects on the surface of the product to ensure that the quality of the product appearance meets the standards.

2, the inner wall inspection: for items with a cavity, such as bottle caps, cups, screws, etc., 360 ° inner wall inspection lens can easily deal with. This lens can be observed from the outside, without the need to place the lens into the product inside, thus avoiding possible secondary damage to the product. Through special imaging technology, the lens can clearly show the defects and characteristics of the inner wall, helping companies to find and solve problems in a timely manner.

3, cylinder and complex structure detection: 360 ° industrial inspection lens is also suitable for cylinder and complex structure detection. Whether it is the outer surface of the cylinder or the surface of the inner hole, the lens can realize all-round, dead-angle-free detection. This feature makes it in automotive manufacturing, aerospace, electronics manufacturing and other fields with a wide range of applications.

With its omni-directional inspection capability, high efficiency and high accuracy, 360° industrial inspection lens plays an increasingly important role in machine vision system, improves product quality and production efficiency, and promotes the process of intelligence and automation of industrial production.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com