With the rapid development of science and technology, precision manufacturing has become an important trend in modern industry. In automated production lines, industrial lenses play a vital role as the core component of machine vision systems. They not only improve production efficiency, but also significantly improve product quality。

The role of industrial lenses in automated production lines

In the automated production line, industrial lenses are the “eyes” of machine vision technology, they are responsible for capturing the image information on the production line and transmitting it to the image processing system for analysis and judgment. Through high-precision image acquisition and processing, industrial lenses are able to monitor various parameters of the product in real time, such as size, appearance, color, etc., to ensure that the product meets the quality standards.

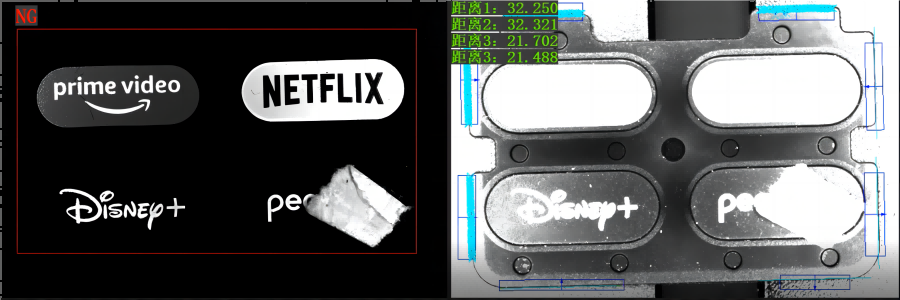

POMEAS Industrial Lenses for Character Inspection

Character detection is an important task in automated production lines, which involves recognizing and verifying characters on the product surface or packaging. These characters usually contain important information such as the product model number, production date, batch number, etc., and are critical for product traceability and quality control. However, character inspection often faces many challenges, such as small characters, complex backgrounds, reflections and other issues. POMEAS industrial lenses show significant advantages in character inspection due to their excellent performance and diverse options.

High resolution and low distortion

POMEAS industrial lenses utilize advanced optical design technology to provide high resolution and low distortion images. This allows characters to be clearly rendered in the image and even tiny characters can be accurately recognized. At the same time, the low distortion feature ensures the realism and accuracy of the image and avoids misjudgment caused by lens distortion.

Highly adaptable

POMEAS industrial lenses are widely adaptable to meet the needs of different types of character inspection. Whether the characters are on metal, plastic or paper, whether they are black, white or colorful, the POMEAS industrial lens provides clear images. In addition, it adapts to different lighting conditions and shooting angles, ensuring stable inspection results in a variety of environments.

Efficient detection

In automated production lines, time is efficiency. The combination of a POMEAS industrial lens and a high-speed industrial camera enables efficient character detection. By optimizing the performance parameters of the lens and the camera, the POMEAS system can detect and identify a large number of characters in a very short time, greatly improving the overall efficiency of the production line.

Case (law)

Taking chip surface character inspection as an example, POMEAS industrial lenses provide a comprehensive solution. Due to the small characters on the chip surface and high precision requirements, ordinary lenses are often difficult to handle. However, by virtue of its high resolution and low distortion characteristics, POMEAS industrial lenses are able to clearly capture the image of the characters on the chip surface. At the same time, with the efficient industrial camera and light source system, it realizes the fast and accurate detection of the characters on the chip surface. This solution not only improves the quality control level of chip production, but also significantly reduces labor costs.

POMEAS industrial lenses have demonstrated excellent performance and wide application prospects in character detection in automated production lines. They not only improve production efficiency and product quality, but also bring significant economic and social benefits to enterprises. With the continuous development and improvement of science and technology, Bumis industrial lenses will play a greater role in more fields and promote precision manufacturing to new heights.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com