Spectral Confocal Sensors for Photovoltaic Panel Quality Inspection

Background

A photovoltaic panel, usually referred to as a solar panel, is a device that absorbs sunlight and converts the sun's radiant energy directly or indirectly into electrical energy through the photovoltaic or photochemical effect. Most solar panels are made of silicon, which is a costly material to produce, so their popularization still faces certain challenges. However, as a more energy-efficient and environmentally friendly green product, solar panels have been widely used in home photovoltaic systems, commercial photovoltaic power plants and other fields.

1, High precision measurement needs: The performance and quality of photovoltaic panels directly affects their power generation efficiency and service life. Spectral confocal sensor with its high-precision measurement capability, can accurately detect the key parameters of the photovoltaic panel, such as thickness, flatness, surface defects, etc., to ensure that the quality of the panel meets the design requirements.

2, Non-contact Measurement Advantage: In the production and inspection process of photovoltaic panels, non-contact measurement can avoid damage and contamination of the panel surface. Spectral confocal sensor using non-contact measurement, can complete the measurement task without contacting the surface of the battery board, to protect the battery board from damage.

3, Fast response and real-time monitoring: Spectral confocal sensors have a fast response characteristics, real-time monitoring of the production process and quality status of photovoltaic panels. This helps to find and solve production problems in a timely manner, improve production efficiency and product quality.

4, Adaptation to complex environments: Photovoltaic panel production and testing environment may be more complex, such as the existence of light changes, temperature changes and other factors. Spectral confocal sensor has a strong environmental adaptability, can maintain stable measurement performance in different environmental conditions.

5, Improve product quality and safety: Through the spectral confocal sensor detection, can be found in a timely manner in the photovoltaic panel defects and problems, to avoid unqualified products into the market. This helps to improve the overall quality and safety of the product, and enhance consumer trust and satisfaction with the product.

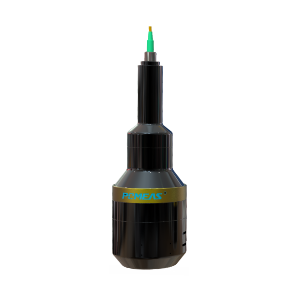

Spectral confocal sensors, such as model PMS-SFS-D8020, play an important role in the quality inspection of photovoltaic panels by virtue of their high accuracy and non-contact measurement. By integrating advanced optical technology and sophisticated signal processing algorithms, spectral confocal sensors are able to accurately measure key parameters such as surface flatness, thickness, and refractive index of PV panels, ensuring that the quality and performance of PV panels meet design requirements.

In the production process of photovoltaic panels, the application of spectral confocal sensors can significantly improve the detection efficiency and accuracy, reduce the rate of defective products, improve production efficiency and product quality. At the same time, it also helps to realize automated production and intelligent management, and promote the transformation and upgrading of the photovoltaic industry and high-quality development.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com